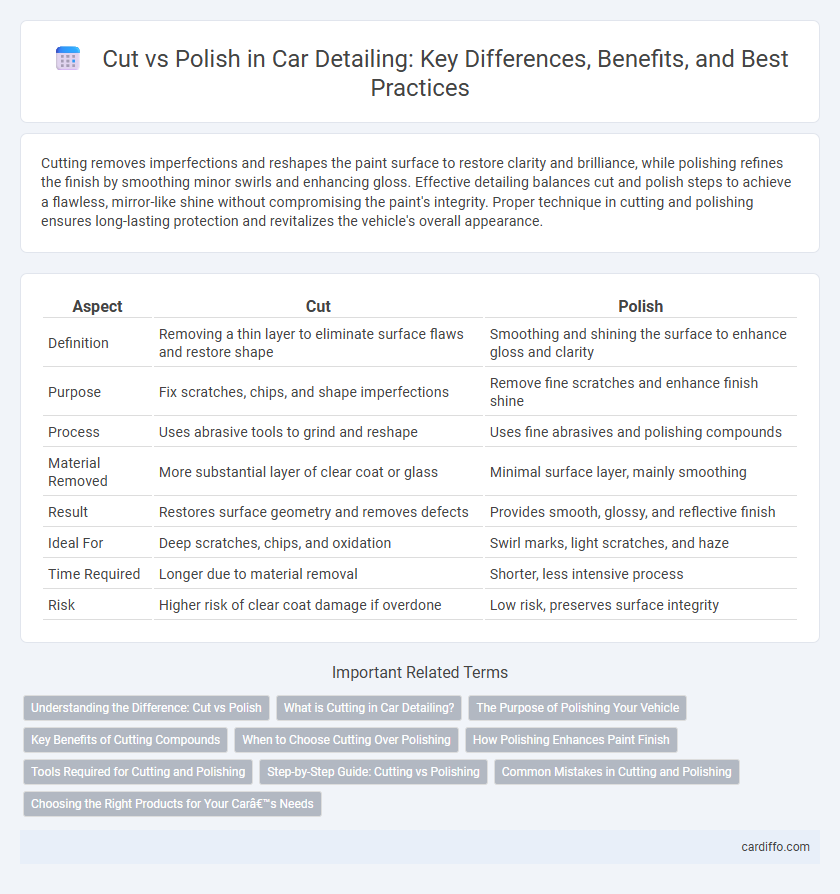

Cutting removes imperfections and reshapes the paint surface to restore clarity and brilliance, while polishing refines the finish by smoothing minor swirls and enhancing gloss. Effective detailing balances cut and polish steps to achieve a flawless, mirror-like shine without compromising the paint's integrity. Proper technique in cutting and polishing ensures long-lasting protection and revitalizes the vehicle's overall appearance.

Table of Comparison

| Aspect | Cut | Polish |

|---|---|---|

| Definition | Removing a thin layer to eliminate surface flaws and restore shape | Smoothing and shining the surface to enhance gloss and clarity |

| Purpose | Fix scratches, chips, and shape imperfections | Remove fine scratches and enhance finish shine |

| Process | Uses abrasive tools to grind and reshape | Uses fine abrasives and polishing compounds |

| Material Removed | More substantial layer of clear coat or glass | Minimal surface layer, mainly smoothing |

| Result | Restores surface geometry and removes defects | Provides smooth, glossy, and reflective finish |

| Ideal For | Deep scratches, chips, and oxidation | Swirl marks, light scratches, and haze |

| Time Required | Longer due to material removal | Shorter, less intensive process |

| Risk | Higher risk of clear coat damage if overdone | Low risk, preserves surface integrity |

Understanding the Difference: Cut vs Polish

Cutting involves removing material from a surface to reshape or level it, commonly used to eliminate deep scratches or imperfections. Polishing smooths and refines the surface by removing only a thin layer, enhancing shine and clarity without altering the overall shape. Understanding the difference between cut and polish ensures effective detailing by matching the process to the severity of surface defects.

What is Cutting in Car Detailing?

Cutting in car detailing refers to the process of removing surface imperfections such as scratches, oxidation, and swirl marks using abrasive compounds and polishing pads. This technique restores the paint's clarity by leveling out the damaged layers and revealing a smoother, more reflective surface. Proper cutting enhances the vehicle's overall appearance and prepares it for subsequent polishing and waxing steps.

The Purpose of Polishing Your Vehicle

Polishing your vehicle enhances the paint's clarity and depth by removing minor imperfections such as swirl marks and light scratches that cutting alone cannot eliminate. It prepares the surface for waxing or sealing, ensuring the protective layers adhere more effectively for long-lasting shine and protection. This process restores the vehicle's gloss, amplifying its aesthetic appeal while maintaining the integrity of the clear coat.

Key Benefits of Cutting Compounds

Cutting compounds offer superior abrasive action that effectively removes deep scratches, oxidation, and stubborn surface imperfections from paintwork, restoring clarity and smoothness. Their fast-cutting ability dramatically reduces correction time, making them ideal for heavy paint correction tasks. Using cutting compounds also preps the surface for finer polishing steps, enhancing the overall finish and durability of automotive paint protection.

When to Choose Cutting Over Polishing

Cutting should be chosen over polishing when surface imperfections such as scratches, oxidation, or heavy swirl marks need to be removed, as cutting uses abrasive compounds to level the paint surface. Polishing is ideal for light defects and enhancing gloss without significant material removal, whereas cutting restores severely damaged finishes by removing a thin layer of clear coat. Selecting cutting ensures deeper correction for vehicles with aged, weathered, or heavily damaged paint.

How Polishing Enhances Paint Finish

Polishing enhances paint finish by removing microscopic imperfections and swirl marks, resulting in a smoother and glossier surface. This process refines the clear coat, amplifying light reflection to produce a deep, mirror-like shine. Regular polishing also helps prolong the durability of the paint by sealing minor scratches and preventing oxidation.

Tools Required for Cutting and Polishing

Cutting requires precision tools such as diamond-tipped blades, rotary cutters, and specialized saws to ensure clean and accurate cuts on various materials. Polishing demands abrasive materials like polishing pads, buffing wheels, and compounds designed to smooth surfaces and enhance shine. Both processes rely heavily on electric or pneumatic power tools optimized for speed and control to achieve professional results.

Step-by-Step Guide: Cutting vs Polishing

Cutting involves shaping the surface of a material by removing layers through grinding or sanding, focusing on rough refinement to achieve the desired form. Polishing follows cutting and uses finer abrasives and buffing techniques to smooth the surface, enhance gloss, and eliminate scratches for a mirror-like finish. This step-by-step process ensures precision in shaping during cutting, followed by surface perfection in polishing for superior detail quality.

Common Mistakes in Cutting and Polishing

Common mistakes in cutting and polishing include improper facet alignment, which reduces a gemstone's brilliance, and excessive polishing that can wear down detail and clarity. Overcutting often leads to uneven surfaces and light leakage, diminishing overall beauty and value. Precise cutting angles and controlled polishing techniques are crucial to maintain a gemstone's optical performance and durability.

Choosing the Right Products for Your Car’s Needs

Selecting the appropriate cut or polish product depends on your car's paint condition and desired finish; cutting compounds effectively remove deep scratches and oxidation, while polishing products enhance gloss and smooth minor imperfections. For heavily damaged surfaces, a medium to heavy cut compound combined with a dual-action polisher provides optimal restoration results. Using the right product ensures protection of clear coats and preserves the vehicle's factory finish while delivering a high-quality, showroom shine.

Cut vs Polish Infographic

cardiffo.com

cardiffo.com