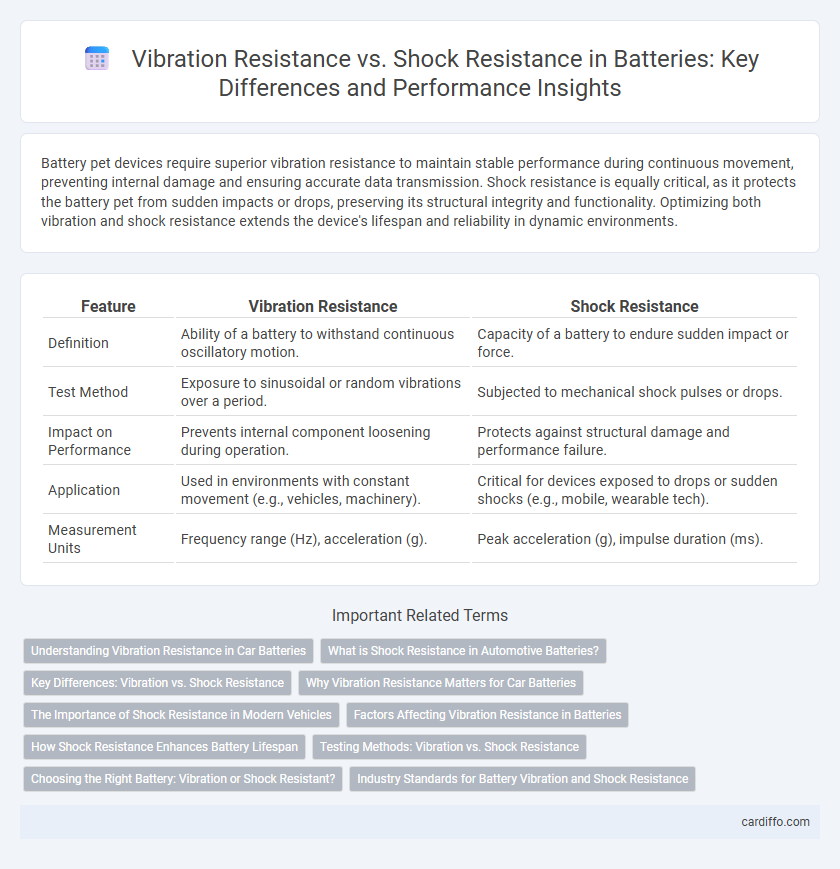

Battery pet devices require superior vibration resistance to maintain stable performance during continuous movement, preventing internal damage and ensuring accurate data transmission. Shock resistance is equally critical, as it protects the battery pet from sudden impacts or drops, preserving its structural integrity and functionality. Optimizing both vibration and shock resistance extends the device's lifespan and reliability in dynamic environments.

Table of Comparison

| Feature | Vibration Resistance | Shock Resistance |

|---|---|---|

| Definition | Ability of a battery to withstand continuous oscillatory motion. | Capacity of a battery to endure sudden impact or force. |

| Test Method | Exposure to sinusoidal or random vibrations over a period. | Subjected to mechanical shock pulses or drops. |

| Impact on Performance | Prevents internal component loosening during operation. | Protects against structural damage and performance failure. |

| Application | Used in environments with constant movement (e.g., vehicles, machinery). | Critical for devices exposed to drops or sudden shocks (e.g., mobile, wearable tech). |

| Measurement Units | Frequency range (Hz), acceleration (g). | Peak acceleration (g), impulse duration (ms). |

Understanding Vibration Resistance in Car Batteries

Vibration resistance in car batteries refers to the ability to withstand continuous mechanical oscillations without performance degradation or physical damage. This property is crucial because constant engine vibrations and road conditions can loosen internal components or cause electrode shedding, reducing battery lifespan. High-quality vibration-resistant batteries utilize reinforced plates and advanced separators to maintain structural integrity and ensure reliable power delivery under dynamic driving conditions.

What is Shock Resistance in Automotive Batteries?

Shock resistance in automotive batteries refers to the battery's ability to withstand sudden and intense physical impacts without damage or performance degradation. This characteristic is crucial for vehicles operating on rough roads or during collisions, ensuring consistent electrical output and longer battery life. High shock resistance is achieved through robust internal construction and reinforced casing materials designed to absorb and dissipate impact energy effectively.

Key Differences: Vibration vs. Shock Resistance

Vibration resistance refers to a battery's ability to endure continuous, repetitive oscillations without performance degradation, while shock resistance denotes its capacity to withstand sudden, high-impact forces without physical damage or loss of functionality. Vibration tests simulate operational environments with ongoing mechanical oscillations, whereas shock tests replicate instant impacts from drops or collisions. Understanding these differences is crucial for selecting batteries in applications requiring durability against either sustained vibrations or abrupt shocks.

Why Vibration Resistance Matters for Car Batteries

Vibration resistance is crucial for car batteries because constant engine vibrations can cause internal damage, leading to reduced battery life and performance. Batteries designed with enhanced vibration resistance maintain stable electrical connections and prevent plate deformation, ensuring reliable power delivery even on rough roads. This durability is essential for vehicles frequently driven in challenging conditions, where shocks alone do not fully represent the mechanical stresses experienced.

The Importance of Shock Resistance in Modern Vehicles

Shock resistance is crucial in modern vehicles to protect batteries from sudden impacts during collisions or rough terrain navigation, ensuring consistent power delivery and safety. Advanced shock-resistant batteries incorporate robust casings and internal cushioning materials that absorb and dissipate kinetic energy, preventing damage to critical cells and internal connections. This durability directly enhances vehicle reliability, reduces maintenance costs, and supports the longevity of electric and hybrid vehicle powertrains.

Factors Affecting Vibration Resistance in Batteries

Factors affecting vibration resistance in batteries include electrode material composition, internal cell design, and the quality of seals that prevent electrolyte leakage. The mechanical flexibility of the battery casing and the type of mounting system used in devices also significantly influence durability under continuous vibration stress. Temperature variations and exposure to harsh environmental conditions may further degrade the vibration resistance capacity of the battery over time.

How Shock Resistance Enhances Battery Lifespan

Shock resistance enhances battery lifespan by minimizing internal damage caused by sudden impacts, preserving electrode integrity and preventing capacity loss. Batteries designed with shock-absorbing materials and robust casing maintain stable performance in harsh environments, reducing the risk of short circuits and electrolyte leakage. This durability ensures longer operational life and reliable energy delivery in devices exposed to mechanical shocks.

Testing Methods: Vibration vs. Shock Resistance

Vibration resistance testing typically involves subjecting batteries to continuous oscillatory motion at various frequencies and amplitudes to simulate real-world mechanical stresses, ensuring structural integrity and performance stability. Shock resistance testing applies sudden, high-impact forces such as drops or collisions, measured by peak acceleration and duration, to evaluate the battery's ability to withstand abrupt mechanical shocks without damage or failure. Both testing methods follow standardized protocols like IEC 62133 and MIL-STD-810 for reliable assessment of battery durability under different physical stress conditions.

Choosing the Right Battery: Vibration or Shock Resistant?

Choosing the right battery depends on the specific environmental stresses it will encounter, with vibration-resistant batteries designed to withstand constant mechanical oscillations and shock-resistant batteries engineered to endure sudden impacts or drops. Vibration resistance is critical for applications in automotive or industrial machinery where continuous motion occurs, while shock resistance is essential for devices exposed to accidental falls or abrupt forces, such as portable electronics. Evaluating the operational conditions helps determine whether vibration or shock resistance is a priority for ensuring battery longevity and performance.

Industry Standards for Battery Vibration and Shock Resistance

Industry standards for battery vibration and shock resistance are defined by rigorous testing protocols such as IEC 62133 and UN 38.3, which ensure safety and durability under mechanical stress. Vibration resistance standards typically involve sinusoidal and random vibration tests to simulate operational conditions, while shock resistance standards require batteries to withstand impact shocks and drops without loss of performance or structural damage. Compliance with these standards guarantees battery reliability in automotive, aerospace, and industrial applications where mechanical stresses are prevalent.

Vibration Resistance vs Shock Resistance Infographic

cardiffo.com

cardiffo.com