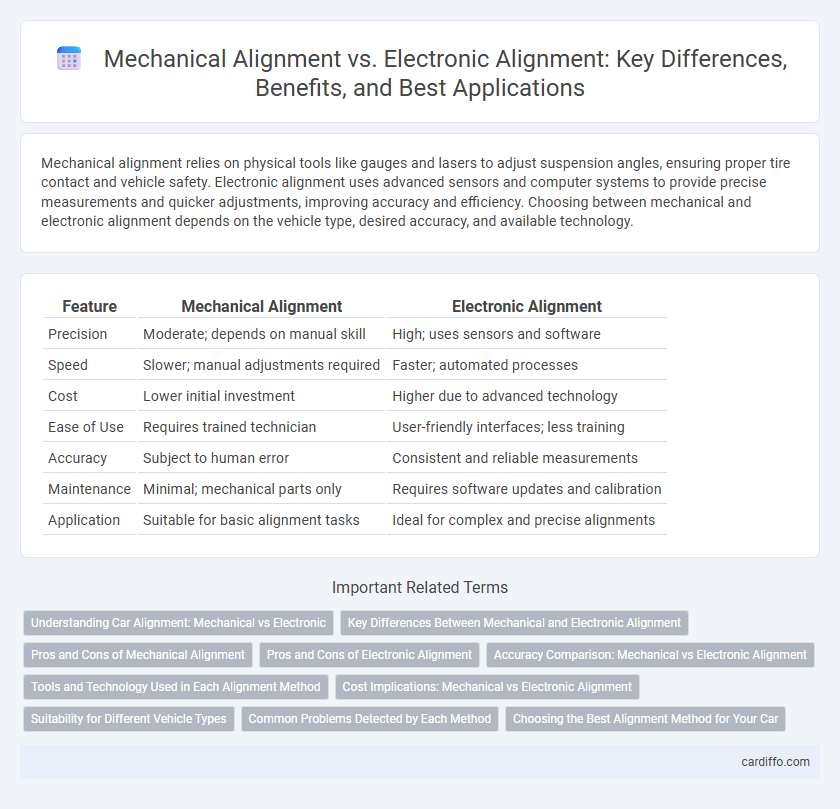

Mechanical alignment relies on physical tools like gauges and lasers to adjust suspension angles, ensuring proper tire contact and vehicle safety. Electronic alignment uses advanced sensors and computer systems to provide precise measurements and quicker adjustments, improving accuracy and efficiency. Choosing between mechanical and electronic alignment depends on the vehicle type, desired accuracy, and available technology.

Table of Comparison

| Feature | Mechanical Alignment | Electronic Alignment |

|---|---|---|

| Precision | Moderate; depends on manual skill | High; uses sensors and software |

| Speed | Slower; manual adjustments required | Faster; automated processes |

| Cost | Lower initial investment | Higher due to advanced technology |

| Ease of Use | Requires trained technician | User-friendly interfaces; less training |

| Accuracy | Subject to human error | Consistent and reliable measurements |

| Maintenance | Minimal; mechanical parts only | Requires software updates and calibration |

| Application | Suitable for basic alignment tasks | Ideal for complex and precise alignments |

Understanding Car Alignment: Mechanical vs Electronic

Mechanical alignment uses physical tools like camber gauges and turn plates to adjust the vehicle's suspension angles, ensuring tire contact and proper handling. Electronic alignment employs advanced sensors and computer systems to measure and correct alignment with greater precision, often providing real-time data for optimal adjustments. Understanding the differences between mechanical and electronic alignment helps in selecting the right method for accurate suspension tuning and improved driving safety.

Key Differences Between Mechanical and Electronic Alignment

Mechanical alignment relies on physical tools such as dial indicators, laser guides, and feeler gauges to manually adjust machinery components, while electronic alignment employs advanced sensors and computerized systems for precise measurements and automated corrections. Electronic alignment offers higher accuracy, real-time data monitoring, and faster adjustment processes compared to the time-consuming and skill-dependent nature of mechanical methods. The key differences include the level of precision, efficiency, and the ability to integrate with digital monitoring platforms, making electronic alignment more suitable for complex and high-performance machinery.

Pros and Cons of Mechanical Alignment

Mechanical alignment offers direct physical adjustments ensuring precise control of components, which enhances durability and reduces dependency on software errors. Its simplicity and reliability make it cost-effective and easier to maintain compared to electronic systems. However, mechanical alignment lacks the adaptability and dynamic correction capabilities found in electronic alignment systems, limiting performance in complex or variable conditions.

Pros and Cons of Electronic Alignment

Electronic alignment offers precise adjustments using advanced sensors and software, significantly reducing human error compared to mechanical methods. It enables faster setup and real-time feedback, enhancing efficiency and accuracy in complex systems. However, reliance on electronic components may introduce higher costs and potential vulnerability to technical malfunctions.

Accuracy Comparison: Mechanical vs Electronic Alignment

Mechanical alignment relies on manual adjustments using physical tools, often resulting in limited precision due to human error and equipment wear. Electronic alignment employs sensors and computerized systems to measure and correct alignment with high accuracy, reducing variability and ensuring consistent results. Studies show electronic alignment improves accuracy by up to 30% compared to traditional mechanical methods, making it the preferred choice for precision-sensitive applications.

Tools and Technology Used in Each Alignment Method

Mechanical alignment relies on physical tools such as camber gauges, toe plates, and pry bars to manually adjust suspension components, ensuring proper wheel angles. Electronic alignment employs advanced sensors, laser measurement systems, and computer software to provide precise, real-time data and automatic adjustments for optimal alignment accuracy. The integration of digital technology in electronic alignment reduces human error and enhances efficiency compared to the traditional mechanical approach.

Cost Implications: Mechanical vs Electronic Alignment

Mechanical alignment typically incurs lower upfront costs due to simpler equipment and fewer advanced components, making it suitable for basic alignment tasks. Electronic alignment, while involving higher initial investment for sensors and software, offers greater precision and reduced long-term maintenance expenses by minimizing alignment errors and downtime. Businesses must consider total cost of ownership, factoring in equipment durability, accuracy requirements, and potential productivity gains when choosing between mechanical and electronic alignment solutions.

Suitability for Different Vehicle Types

Mechanical alignment is ideal for traditional vehicles with straightforward suspension systems, providing precise adjustments through physical components such as tie rods and control arms. Electronic alignment suits modern vehicles equipped with advanced driver-assistance systems (ADAS), using sensors and cameras to achieve highly accurate calibrations crucial for safety features. Each method aligns best with the vehicle's technology level and suspension complexity, ensuring optimal performance and safety.

Common Problems Detected by Each Method

Mechanical alignment commonly detects issues such as wheel misalignment, uneven tire wear, and suspension component wear by physically measuring angles and positions. Electronic alignment uses sensors and computer diagnostics to identify problems including sensor malfunctions, electronic control unit errors, and dynamic misalignment during vehicle operation. Both methods reveal critical faults, but electronic alignment offers real-time data on vehicle behavior that mechanical alignment cannot capture.

Choosing the Best Alignment Method for Your Car

Mechanical alignment uses physical tools and manual adjustments to set your car's wheels, offering a cost-effective and reliable solution for basic alignment needs. Electronic alignment employs advanced sensors and computer systems to provide precise measurements and automated adjustments, ideal for modern vehicles with complex suspension systems. Choosing the best alignment method depends on your car's technology level, budget, and desired accuracy, with electronic alignment favored for newer models and mechanical alignment suited for older or simpler vehicles.

Mechanical Alignment vs Electronic Alignment Infographic

cardiffo.com

cardiffo.com