A single mass flywheel offers a simpler, lighter design that improves throttle response and reduces engine rev time, ideal for performance upgrades. Dual mass flywheels provide superior vibration dampening and smoother operation, enhancing comfort and longevity in everyday driving. Choosing between the two depends on balancing driving style preferences with desired engine performance and noise reduction.

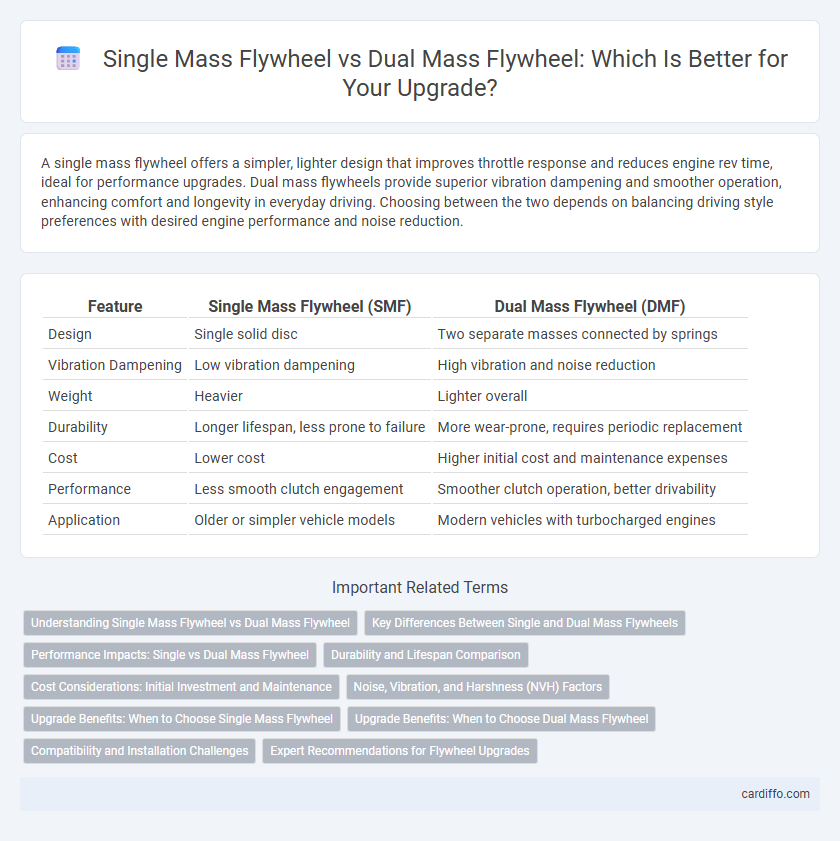

Table of Comparison

| Feature | Single Mass Flywheel (SMF) | Dual Mass Flywheel (DMF) |

|---|---|---|

| Design | Single solid disc | Two separate masses connected by springs |

| Vibration Dampening | Low vibration dampening | High vibration and noise reduction |

| Weight | Heavier | Lighter overall |

| Durability | Longer lifespan, less prone to failure | More wear-prone, requires periodic replacement |

| Cost | Lower cost | Higher initial cost and maintenance expenses |

| Performance | Less smooth clutch engagement | Smoother clutch operation, better drivability |

| Application | Older or simpler vehicle models | Modern vehicles with turbocharged engines |

Understanding Single Mass Flywheel vs Dual Mass Flywheel

Single mass flywheels are made from a single piece of metal, offering durability and simpler construction, ideal for performance and heavy-duty applications. Dual mass flywheels incorporate two separate masses connected by springs to absorb engine vibrations, improving ride comfort and reducing drivetrain noise. Choosing between single mass and dual mass flywheels depends on vehicle type, driving conditions, and desired balance between performance and smoothness.

Key Differences Between Single and Dual Mass Flywheels

Single mass flywheels are constructed from a single solid piece of metal, offering durability and a straightforward design ideal for high-performance applications and manual transmissions. Dual mass flywheels consist of two separate masses connected by a damping system, which reduces engine vibrations and provides smoother operation, especially beneficial in modern vehicles with sensitive drivetrains. Key differences include weight, vibration absorption, cost, and maintenance complexity, with dual mass flywheels being heavier, more expensive, and requiring more frequent replacement compared to the simpler, lighter single mass flywheels.

Performance Impacts: Single vs Dual Mass Flywheel

Single mass flywheels provide a more direct and responsive connection between the engine and transmission, resulting in improved throttle response and enhanced performance during aggressive driving. Dual mass flywheels excel at dampening engine vibrations and reducing noise, which contributes to smoother operation and increased comfort but may slightly reduce power transmission efficiency. Upgrading to a single mass flywheel is often favored in performance applications for its durability and quicker acceleration feedback, while dual mass flywheels remain preferred for everyday driving to optimize drivability and reduce drivetrain wear.

Durability and Lifespan Comparison

Single mass flywheels typically offer greater durability due to their simpler design and fewer moving parts, resulting in a longer lifespan under standard driving conditions. Dual mass flywheels, while designed to reduce vibration and improve comfort, have a more complex structure that can lead to earlier wear and require replacement more frequently. For vehicles used in heavy-duty or high-torque applications, single mass flywheels generally provide a more reliable and long-lasting solution.

Cost Considerations: Initial Investment and Maintenance

Single mass flywheels typically have a lower initial purchase price and reduced replacement costs compared to dual mass flywheels, making them a cost-effective option for budget-conscious vehicle owners. Maintenance expenses are generally lower for single mass flywheels due to their simpler construction and fewer moving parts, which results in less frequent repairs and replacements. However, dual mass flywheels, while more expensive upfront and costly to maintain, offer improved vibration dampening and engine protection that can reduce long-term drivetrain damage and associated repair costs.

Noise, Vibration, and Harshness (NVH) Factors

Single mass flywheels generally produce higher NVH levels due to their rigid structure, leading to increased noise and vibration transferred to the chassis. Dual mass flywheels incorporate an internal damping mechanism that significantly reduces torsional vibrations, resulting in smoother operation and lower noise emissions. Vehicles utilizing dual mass flywheels benefit from enhanced driving comfort and extended drivetrain longevity by mitigating harshness and mechanical resonance.

Upgrade Benefits: When to Choose Single Mass Flywheel

Choosing a single mass flywheel upgrade is ideal for performance vehicles and drivers seeking improved throttle response and reduced drivetrain lash. Single mass flywheels offer increased durability and simpler construction, making them suitable for high RPM applications and aggressive driving styles. Their reduced rotational mass enhances engine revving capabilities, delivering faster acceleration and a more direct connection to the engine.

Upgrade Benefits: When to Choose Dual Mass Flywheel

Dual mass flywheels significantly reduce drivetrain vibrations and improve driving comfort, making them ideal for vehicles with high torque outputs and modern diesel engines. Upgrading to a dual mass flywheel enhances gear shifting smoothness and minimizes noise, leading to increased longevity of transmission components. Choosing this upgrade benefits heavy-duty applications and stop-and-go driving conditions where vibration dampening is critical.

Compatibility and Installation Challenges

Single mass flywheels offer broader compatibility across various vehicle models due to their simpler design, but they may not fit all engines originally designed for dual mass flywheels. Dual mass flywheels require precise alignment and specialized tools during installation, increasing complexity and potential for error compared to the straightforward mounting of single mass flywheels. Upgrading from dual mass to single mass can necessitate additional modifications to the clutch system and may impact vibration damping characteristics.

Expert Recommendations for Flywheel Upgrades

Expert recommendations for flywheel upgrades emphasize choosing a dual mass flywheel (DMF) for enhanced vibration damping and improved driving comfort in modern vehicles equipped with high-torque engines. Single mass flywheels (SMF) are preferred in performance applications due to their lighter weight and quicker engine response, although they may transmit more vibrations. Selecting the appropriate flywheel depends on vehicle usage, with experts advising DMFs for OEM replacements and SMFs for racing or high-performance modifications.

Single mass flywheel vs dual mass flywheel Infographic

cardiffo.com

cardiffo.com