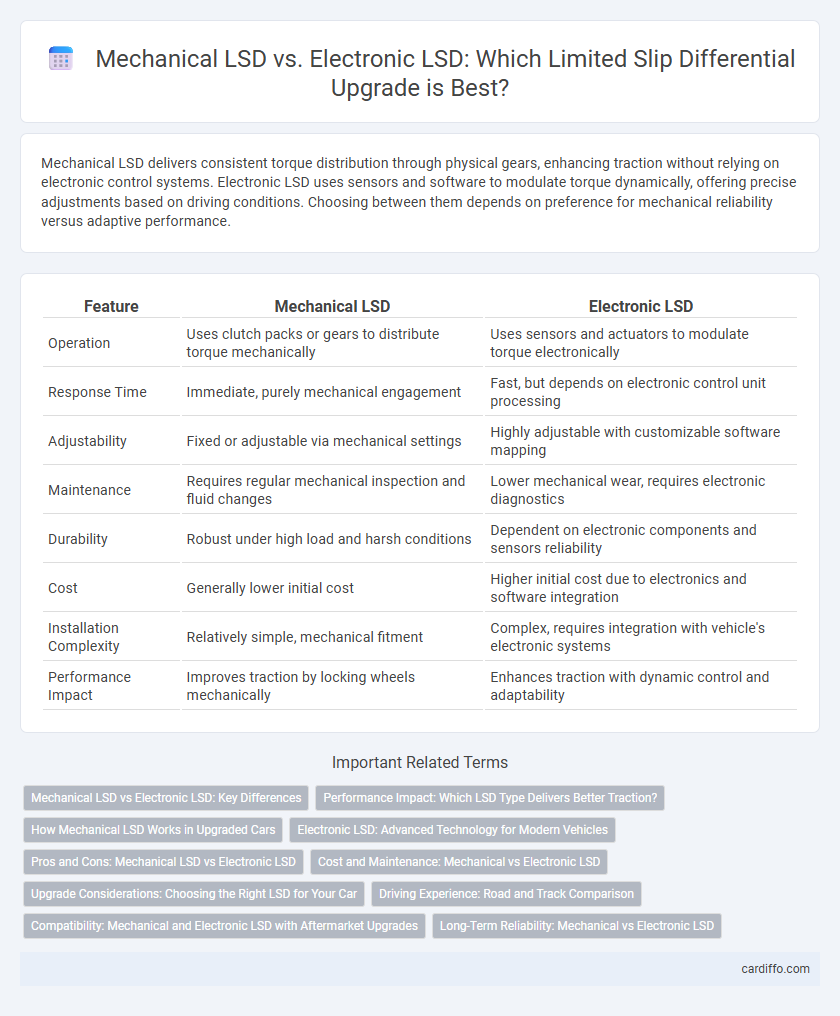

Mechanical LSD delivers consistent torque distribution through physical gears, enhancing traction without relying on electronic control systems. Electronic LSD uses sensors and software to modulate torque dynamically, offering precise adjustments based on driving conditions. Choosing between them depends on preference for mechanical reliability versus adaptive performance.

Table of Comparison

| Feature | Mechanical LSD | Electronic LSD |

|---|---|---|

| Operation | Uses clutch packs or gears to distribute torque mechanically | Uses sensors and actuators to modulate torque electronically |

| Response Time | Immediate, purely mechanical engagement | Fast, but depends on electronic control unit processing |

| Adjustability | Fixed or adjustable via mechanical settings | Highly adjustable with customizable software mapping |

| Maintenance | Requires regular mechanical inspection and fluid changes | Lower mechanical wear, requires electronic diagnostics |

| Durability | Robust under high load and harsh conditions | Dependent on electronic components and sensors reliability |

| Cost | Generally lower initial cost | Higher initial cost due to electronics and software integration |

| Installation Complexity | Relatively simple, mechanical fitment | Complex, requires integration with vehicle's electronic systems |

| Performance Impact | Improves traction by locking wheels mechanically | Enhances traction with dynamic control and adaptability |

Mechanical LSD vs Electronic LSD: Key Differences

Mechanical LSDs use clutch plates to physically distribute torque between wheels, offering predictable traction under high-stress conditions without electronic intervention. Electronic LSDs rely on sensors and the vehicle's ECU to modulate braking or torque, providing adaptive traction control that can adjust dynamically to driving conditions. Mechanical LSDs prioritize durability and consistent performance, while electronic LSDs excel in flexibility and integration with modern stability systems.

Performance Impact: Which LSD Type Delivers Better Traction?

Mechanical LSDs provide consistent traction by physically distributing torque between wheels, ensuring reliable grip during high-performance driving and off-road conditions. Electronic LSDs utilize sensors and computer-controlled actuators to modulate torque distribution dynamically, offering precise traction control and adaptability to varying road surfaces. Performance-wise, mechanical LSDs excel in durability and predictable engagement for aggressive driving, while electronic LSDs deliver superior responsiveness and versatility, enhancing traction under diverse driving scenarios.

How Mechanical LSD Works in Upgraded Cars

Mechanical LSD in upgraded cars works by using gears and a clutch mechanism to distribute torque between wheels, enhancing traction during cornering and slippery conditions. It operates based on the difference in wheel speed, engaging the locker to prevent excessive wheel spin without electronic intervention. This purely mechanical system improves handling performance by providing consistent torque transfer, especially in high-performance and off-road vehicles.

Electronic LSD: Advanced Technology for Modern Vehicles

Electronic LSD utilizes sensors and computer-controlled actuators to deliver precise torque distribution between wheels, enhancing traction and stability on varied road conditions. Unlike traditional mechanical LSD, it adapts instantaneously to driving dynamics, improving cornering performance and reducing wheel slippage. This advanced technology integrates seamlessly with vehicle stability control systems, providing superior handling and safety in modern cars.

Pros and Cons: Mechanical LSD vs Electronic LSD

Mechanical LSDs provide consistent torque distribution and enhanced durability, making them ideal for high-performance and off-road applications, but they can cause drivetrain binding and require regular maintenance. Electronic LSDs offer adaptive torque control and smoother operation through real-time sensor inputs, improving traction under varying conditions, though they can be more complex and expensive to repair. Choosing between mechanical and electronic LSDs depends on the driving environment, with mechanical units favored for aggressive use and electronic versions preferred for everyday versatility.

Cost and Maintenance: Mechanical vs Electronic LSD

Mechanical LSDs typically have lower upfront costs and simpler maintenance due to their purely mechanical components, making them more affordable for long-term ownership. Electronic LSDs involve higher initial investment and complex electronic systems that can increase both repair complexity and maintenance expenses. Mechanical LSDs offer a cost-effective solution with easier upkeep, while electronic LSDs provide advanced performance features at a higher financial and maintenance commitment.

Upgrade Considerations: Choosing the Right LSD for Your Car

Mechanical LSDs offer robust durability and consistent torque distribution, making them ideal for aggressive driving and off-road conditions. Electronic LSDs provide variable torque control through sensors and ECU integration, enhancing traction and stability in everyday driving and performance scenarios. When upgrading, consider your driving style, vehicle application, and budget to select between the mechanical LSD's reliability and the electronic LSD's adaptability.

Driving Experience: Road and Track Comparison

Mechanical LSDs deliver consistent torque distribution through purely mechanical means, enhancing vehicle stability and traction during aggressive cornering on both road and track. Electronic LSDs use sensors and electronics to modulate torque dynamically, providing adaptable performance that adjusts to varying driving conditions for improved control and precision. On the track, mechanical LSDs often offer more predictable feedback under high stress, while electronic LSDs excel in versatility, optimizing grip and handling across diverse road surfaces.

Compatibility: Mechanical and Electronic LSD with Aftermarket Upgrades

Mechanical LSDs offer broad compatibility with aftermarket upgrades due to their purely mechanical design, ensuring reliable torque distribution without reliance on electronic systems. Electronic LSDs can provide adaptive traction control and integrate seamlessly with vehicle stability programs but may face compatibility challenges when combined with certain non-OEM aftermarket parts or custom tuning. Selecting the appropriate LSD depends on the specific vehicle model, existing electronic systems, and intended modifications to maintain optimal performance and drivetrain harmony.

Long-Term Reliability: Mechanical vs Electronic LSD

Mechanical LSDs offer superior long-term reliability due to their robust, purely mechanical components that withstand heat and wear without electronic failures. Electronic LSDs rely on sensors and actuators that may degrade over time, increasing the risk of failure and maintenance costs. Many performance enthusiasts prefer mechanical LSDs for consistent durability in demanding driving conditions.

Mechanical LSD vs electronic LSD Infographic

cardiffo.com

cardiffo.com