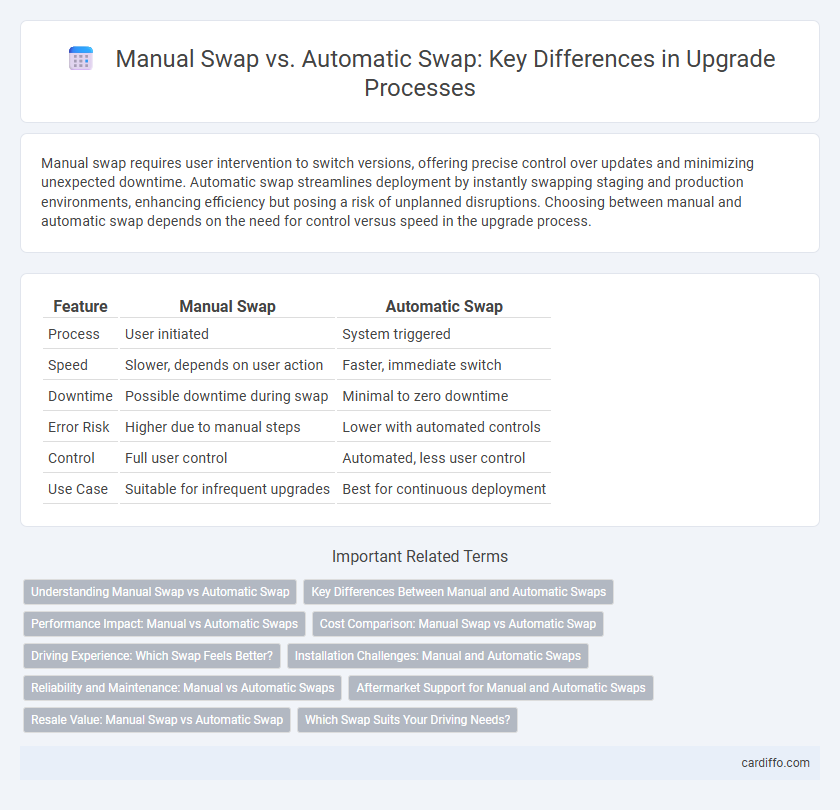

Manual swap requires user intervention to switch versions, offering precise control over updates and minimizing unexpected downtime. Automatic swap streamlines deployment by instantly swapping staging and production environments, enhancing efficiency but posing a risk of unplanned disruptions. Choosing between manual and automatic swap depends on the need for control versus speed in the upgrade process.

Table of Comparison

| Feature | Manual Swap | Automatic Swap |

|---|---|---|

| Process | User initiated | System triggered |

| Speed | Slower, depends on user action | Faster, immediate switch |

| Downtime | Possible downtime during swap | Minimal to zero downtime |

| Error Risk | Higher due to manual steps | Lower with automated controls |

| Control | Full user control | Automated, less user control |

| Use Case | Suitable for infrequent upgrades | Best for continuous deployment |

Understanding Manual Swap vs Automatic Swap

Manual swap requires user intervention to switch app slots during an upgrade, allowing precise control over deployment timing and testing. Automatic swap triggers the slot swap immediately after deployment, minimizing downtime and streamlining continuous integration and delivery processes. Understanding the trade-offs between manual and automatic swaps helps optimize upgrade strategies for reliability and efficiency.

Key Differences Between Manual and Automatic Swaps

Manual swap requires users to initiate the process, offering greater control over timing and execution, while automatic swap triggers the migration instantly upon deployment. Automatic swap minimizes downtime by seamlessly rotating staging and production environments, whereas manual swap may involve brief service interruptions. Key differences include user control level, downtime impact, and the speed of environment transition during application upgrades.

Performance Impact: Manual vs Automatic Swaps

Manual swaps offer greater control over timing, minimizing performance disruptions during upgrades by allowing scheduled, deliberate transitions. Automatic swaps execute immediately upon deployment, potentially causing brief service interruptions due to unplanned resource allocation or configuration changes. Prioritizing manual swaps enhances system stability by reducing unexpected downtime and performance degradation during upgrade processes.

Cost Comparison: Manual Swap vs Automatic Swap

Manual swaps generally incur lower initial costs since they require less infrastructure investment, but they can lead to higher operational expenses due to increased labor and potential downtime. Automatic swaps involve higher upfront costs for automation tools and monitoring systems but reduce ongoing labor costs and enable faster, more reliable upgrade processes. Cost efficiency depends on scale and frequency of swaps, with automatic swaps favored in high-volume environments for long-term savings.

Driving Experience: Which Swap Feels Better?

Manual swap offers drivers direct control over gear changes, delivering a more engaging and tactile driving experience favored by enthusiasts who enjoy precision shifts. Automatic swap provides seamless transitions with minimal driver input, enhancing convenience and comfort on daily commutes or heavy traffic conditions. The subjective preference between manual and automatic swaps ultimately depends on the driver's desire for involvement versus ease of use during gear shifting.

Installation Challenges: Manual and Automatic Swaps

Manual swaps require precise alignment and secure connections during installation, often leading to increased labor time and potential for human error. Automatic swaps reduce installation complexity by relying on pre-configured systems that streamline the process but demand compatible hardware and software environments. Both methods face challenges such as ensuring system downtime is minimized and maintaining data integrity throughout the upgrade.

Reliability and Maintenance: Manual vs Automatic Swaps

Manual swap requires operators to intervene directly, increasing the risk of human error and downtime, which can impact system reliability. Automatic swap systems enhance reliability by enabling seamless transitions without manual input, reducing maintenance interruptions and improving operational continuity. Maintenance demands for manual swaps tend to be higher due to the need for regular inspections and operator training, while automatic swaps prioritize predictive maintenance and remote diagnostics to minimize service disruptions.

Aftermarket Support for Manual and Automatic Swaps

Aftermarket support for manual swaps often includes specialized performance clutches, shift kits, and upgraded flywheels tailored to enthusiast-driven modifications. Automatic swap aftermarket options focus on robust torque converters, transmission control modules, and enhanced cooling systems to improve reliability and shift smoothness. Both swap types benefit from extensive community resources and custom tuning solutions that optimize powertrain compatibility and driving experience.

Resale Value: Manual Swap vs Automatic Swap

Manual swap transmissions often enhance resale value by appealing to driving enthusiasts who value control and engagement, making vehicles more desirable in niche markets. Automatic swaps can broaden market appeal by attracting buyers seeking comfort and ease, potentially increasing resale value in mainstream segments. Resale outcomes depend on factors like vehicle type, buyer preferences, and market trends favoring either manual or automatic drivetrains.

Which Swap Suits Your Driving Needs?

Manual swap allows drivers full control over gear changes, ideal for those who prioritize performance and responsiveness in varied driving conditions. Automatic swap offers convenience and ease, best suited for urban commuting and traffic-heavy environments where smooth and effortless transitions enhance comfort. Assessing your typical driving scenarios and preferences determines which swap aligns with your optimal driving experience.

Manual swap vs automatic swap Infographic

cardiffo.com

cardiffo.com