Forged wheels offer superior strength and durability compared to cast wheels due to their manufacturing process, which involves compressing aluminum under high pressure to create a dense, lightweight structure. Cast wheels are formed by pouring molten aluminum into molds, resulting in a more affordable option but with increased susceptibility to cracks and fatigue over time. Choosing forged wheels enhances vehicle performance and longevity, making them ideal for high-stress driving conditions or performance upgrades.

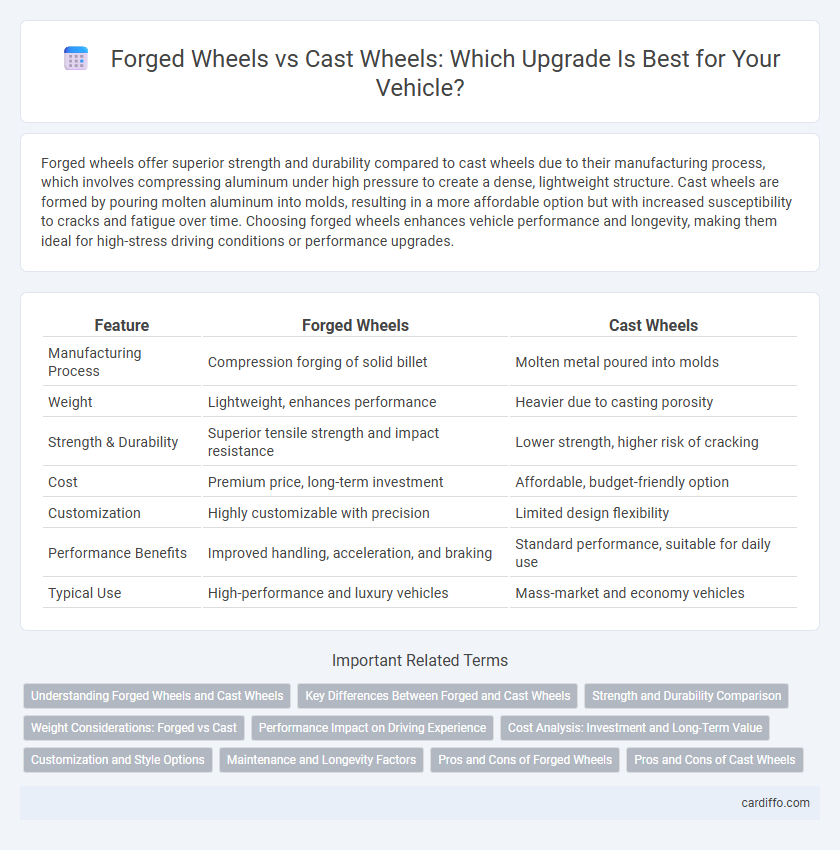

Table of Comparison

| Feature | Forged Wheels | Cast Wheels |

|---|---|---|

| Manufacturing Process | Compression forging of solid billet | Molten metal poured into molds |

| Weight | Lightweight, enhances performance | Heavier due to casting porosity |

| Strength & Durability | Superior tensile strength and impact resistance | Lower strength, higher risk of cracking |

| Cost | Premium price, long-term investment | Affordable, budget-friendly option |

| Customization | Highly customizable with precision | Limited design flexibility |

| Performance Benefits | Improved handling, acceleration, and braking | Standard performance, suitable for daily use |

| Typical Use | High-performance and luxury vehicles | Mass-market and economy vehicles |

Understanding Forged Wheels and Cast Wheels

Forged wheels are crafted from a solid billet of aluminum, subjected to intense heat and pressure, resulting in a denser and stronger structure compared to cast wheels that are formed by pouring molten aluminum into molds. This manufacturing process makes forged wheels lighter, more durable, and better suited for high-performance applications where strength-to-weight ratio is crucial. Cast wheels offer cost-effective production with complex designs but are generally heavier and less resilient under extreme stress, impacting long-term performance and safety.

Key Differences Between Forged and Cast Wheels

Forged wheels offer superior strength and durability due to the high-pressure forging process that aligns the metal's grain structure, resulting in lighter yet more resilient wheels compared to cast wheels. Cast wheels are produced by pouring molten aluminum into molds, making them more affordable but generally heavier and less impact-resistant than forged wheels. The performance benefits of forged wheels include enhanced handling and improved fuel efficiency, making them a preferred choice for high-performance and luxury vehicles.

Strength and Durability Comparison

Forged wheels offer superior strength and durability compared to cast wheels due to their manufacturing process, which involves compressing solid aluminum billets under high pressure, resulting in a denser and more resilient structure. Cast wheels are typically made by pouring molten aluminum into molds, creating a less dense and more brittle composition that is prone to cracking under high stress. This structural advantage of forged wheels makes them ideal for high-performance applications where enhanced resistance to impact and fatigue is critical.

Weight Considerations: Forged vs Cast

Forged wheels typically weigh 20-30% less than cast wheels due to the denser construction process, enhancing vehicle performance and fuel efficiency. Reduced unsprung weight in forged wheels improves acceleration, braking, and handling responsiveness compared to heavier cast alternatives. This weight advantage makes forged wheels a preferred choice for performance enthusiasts seeking optimized driving dynamics.

Performance Impact on Driving Experience

Forged wheels offer significant performance advantages over cast wheels due to their lighter weight and increased strength, resulting in improved acceleration, braking, and handling precision. The reduced unsprung mass enhances suspension responsiveness and overall ride quality, directly benefiting driving dynamics. Cast wheels, while generally more affordable, are heavier and less rigid, which can negatively affect vehicle stability and cornering performance under demanding conditions.

Cost Analysis: Investment and Long-Term Value

Forged wheels typically involve a higher upfront investment due to their intricate manufacturing process and superior material strength, providing enhanced durability and performance over time. Cast wheels offer a more budget-friendly initial cost, but may require more frequent replacements or repairs, affecting long-term value. Evaluating the total cost of ownership, including maintenance and lifespan, highlights forged wheels as a more cost-effective option for enthusiasts prioritizing longevity and quality.

Customization and Style Options

Forged wheels offer superior customization and style options compared to cast wheels, as they can be precisely tailored in shape, size, and finish to match specific vehicle aesthetics. The forging process allows for intricate designs and lightweight construction, enhancing both visual appeal and performance. Cast wheels, while more affordable, typically come with limited design flexibility and heavier weight, which can restrict customization possibilities.

Maintenance and Longevity Factors

Forged wheels exhibit superior durability and resist bending or cracking better than cast wheels due to their denser metal structure, resulting in lower maintenance requirements over time. Cast wheels, while more affordable initially, are prone to micro-fractures and corrosion, often necessitating more frequent inspections and repairs. Choosing forged wheels enhances vehicle longevity and reduces ongoing maintenance costs, making them ideal for performance and long-term investment.

Pros and Cons of Forged Wheels

Forged wheels offer superior strength and durability due to their manufacturing process, which compresses aluminum into a dense structure, making them ideal for high-performance and racing applications. Their lightweight nature improves handling and fuel efficiency but comes with a higher price point compared to cast wheels. The main drawbacks include limited design variety and higher repair costs if damaged.

Pros and Cons of Cast Wheels

Cast wheels offer a cost-effective and versatile option for vehicle upgrades, providing consistent quality and intricate designs due to their manufacturing process. They tend to be heavier than forged wheels, which can impact acceleration and fuel efficiency, and are generally less durable under high-stress conditions like racing or off-roading. However, cast wheels are easier and cheaper to replace or repair, making them a practical choice for everyday driving and budget-conscious buyers.

Forged wheels vs cast wheels Infographic

cardiffo.com

cardiffo.com