Forged pistons offer superior strength and durability compared to cast pistons due to their denser, more uniform structure created under high pressure. They provide enhanced resistance to heat and stress, making them ideal for high-performance and forced induction engines. Cast pistons, while more affordable and suitable for standard applications, lack the robustness required for extreme conditions and frequent upgrades.

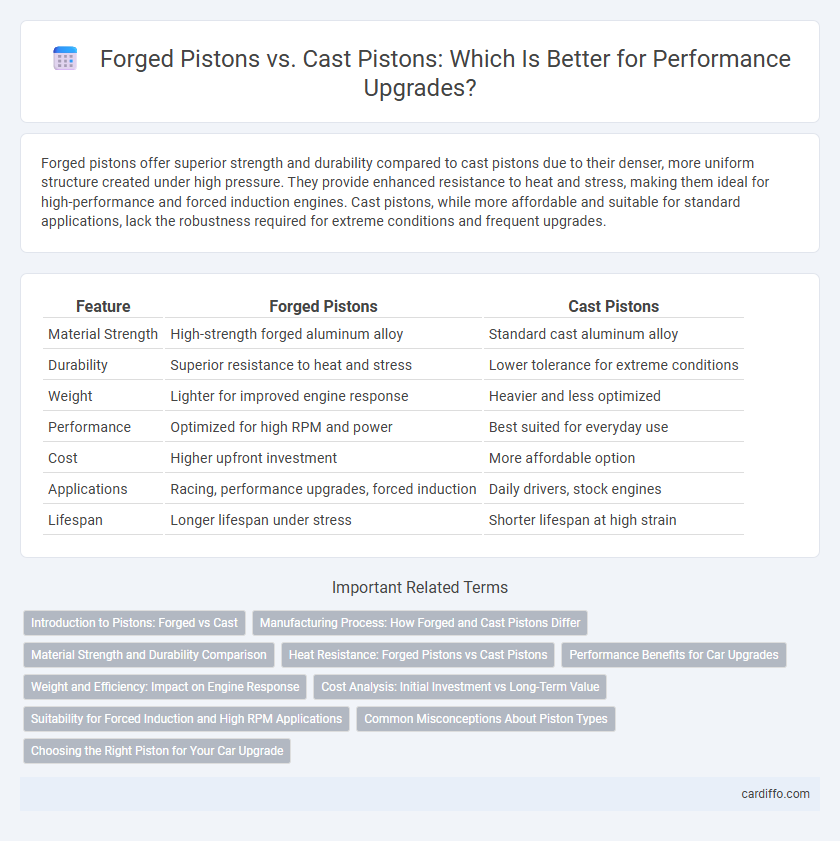

Table of Comparison

| Feature | Forged Pistons | Cast Pistons |

|---|---|---|

| Material Strength | High-strength forged aluminum alloy | Standard cast aluminum alloy |

| Durability | Superior resistance to heat and stress | Lower tolerance for extreme conditions |

| Weight | Lighter for improved engine response | Heavier and less optimized |

| Performance | Optimized for high RPM and power | Best suited for everyday use |

| Cost | Higher upfront investment | More affordable option |

| Applications | Racing, performance upgrades, forced induction | Daily drivers, stock engines |

| Lifespan | Longer lifespan under stress | Shorter lifespan at high strain |

Introduction to Pistons: Forged vs Cast

Forged pistons are crafted by compressing a solid billet of aluminum under high pressure, resulting in a denser and stronger structure ideal for high-performance applications. Cast pistons, made by pouring molten aluminum into molds, offer cost-effective manufacturing with adequate strength for standard engines but less resistance to extreme stress. Understanding the differences in material properties and manufacturing processes helps determine the optimal piston choice for engine upgrades focused on durability and power.

Manufacturing Process: How Forged and Cast Pistons Differ

Forged pistons are produced by compressing a heated billet of aluminum under high pressure, resulting in a dense, uniform microstructure that enhances strength and durability. Cast pistons are created by pouring molten aluminum into a mold, allowing for complex shapes but often yielding a less consistent grain structure. The forged manufacturing process provides superior mechanical properties, making forged pistons ideal for high-performance and high-stress applications compared to cast pistons.

Material Strength and Durability Comparison

Forged pistons are made from a single block of high-strength aluminum alloy, resulting in superior grain structure and enhanced material strength compared to cast pistons, which are created by pouring molten metal into molds. This manufacturing process gives forged pistons increased resistance to mechanical stress and thermal expansion, making them more durable under high-performance and heavy-duty engine conditions. Cast pistons, while more cost-effective and suitable for standard applications, generally exhibit lower tensile strength and are more prone to cracking or deformation under extreme loads.

Heat Resistance: Forged Pistons vs Cast Pistons

Forged pistons exhibit superior heat resistance compared to cast pistons due to their dense, uniform grain structure formed under high pressure, which reduces the likelihood of cracks and deformation under extreme temperatures. Cast pistons, while cost-effective, are more prone to heat-related failures such as melting or warping because of their porous microstructure. This improved thermal durability makes forged pistons ideal for high-performance engines requiring consistent operation under intense heat conditions.

Performance Benefits for Car Upgrades

Forged pistons deliver superior strength and durability compared to cast pistons, allowing engines to withstand higher combustion pressures and temperatures during performance upgrades. Their enhanced resistance to cracking and deformation improves overall engine reliability, especially in high-boost or high-RPM applications. Upgrading to forged pistons can significantly increase power output and engine longevity, making them the preferred choice for serious automotive enthusiasts seeking optimal performance gains.

Weight and Efficiency: Impact on Engine Response

Forged pistons are significantly lighter and stronger than cast pistons, which reduces reciprocating mass and improves engine response. The reduced weight enhances acceleration and throttle sensitivity by allowing the engine to rev more freely and quickly. This results in increased overall efficiency and performance, particularly in high-stress, high-RPM conditions.

Cost Analysis: Initial Investment vs Long-Term Value

Forged pistons typically have a higher initial cost compared to cast pistons due to their complex manufacturing process and superior strength. Although more expensive upfront, forged pistons offer greater durability and resistance to stress, leading to reduced replacement frequency and lower long-term maintenance costs. Cast pistons offer a more affordable entry point but may incur higher expenses over time due to their susceptibility to wear and potential need for earlier replacement.

Suitability for Forced Induction and High RPM Applications

Forged pistons are highly suitable for forced induction and high RPM applications due to their superior strength and resistance to thermal and mechanical stress compared to cast pistons. Their dense structure allows them to withstand the increased cylinder pressures and elevated temperatures found in turbocharged or supercharged engines, reducing the risk of cracking or deformation. Cast pistons, while more cost-effective, lack the durability needed for extreme conditions, making forged pistons the preferred choice for performance upgrades requiring reliability and longevity.

Common Misconceptions About Piston Types

Misconceptions about forged and cast pistons often stem from outdated performance assumptions. Forged pistons are traditionally thought to always outperform cast pistons in strength and durability; however, advancements in casting technology have significantly improved the integrity and thermal resistance of cast pistons. Choosing the right piston type depends more on the specific engine application and intended use rather than a simple forged-versus-cast debate.

Choosing the Right Piston for Your Car Upgrade

Forged pistons offer superior strength and durability due to their dense, uniform grain structure, making them ideal for high-performance or forced induction engine upgrades. Cast pistons are more cost-effective and suitable for standard or mildly tuned engines, providing adequate performance with less risk of cracking under typical driving conditions. Selecting the right piston depends on your car's intended use, power targets, and budget, with forged pistons preferred for aggressive builds and cast pistons fitting everyday upgrades.

Forged Pistons vs Cast Pistons Infographic

cardiffo.com

cardiffo.com