Dry carbon fiber offers superior strength-to-weight ratio and enhanced stiffness compared to wet carbon fiber, making it ideal for high-performance upgrades. The manufacturing process of dry carbon fiber allows for precise resin control, resulting in lighter and more durable components. Wet carbon fiber remains cost-effective and versatile for general applications but lacks the advanced mechanical properties of dry carbon fiber alternatives.

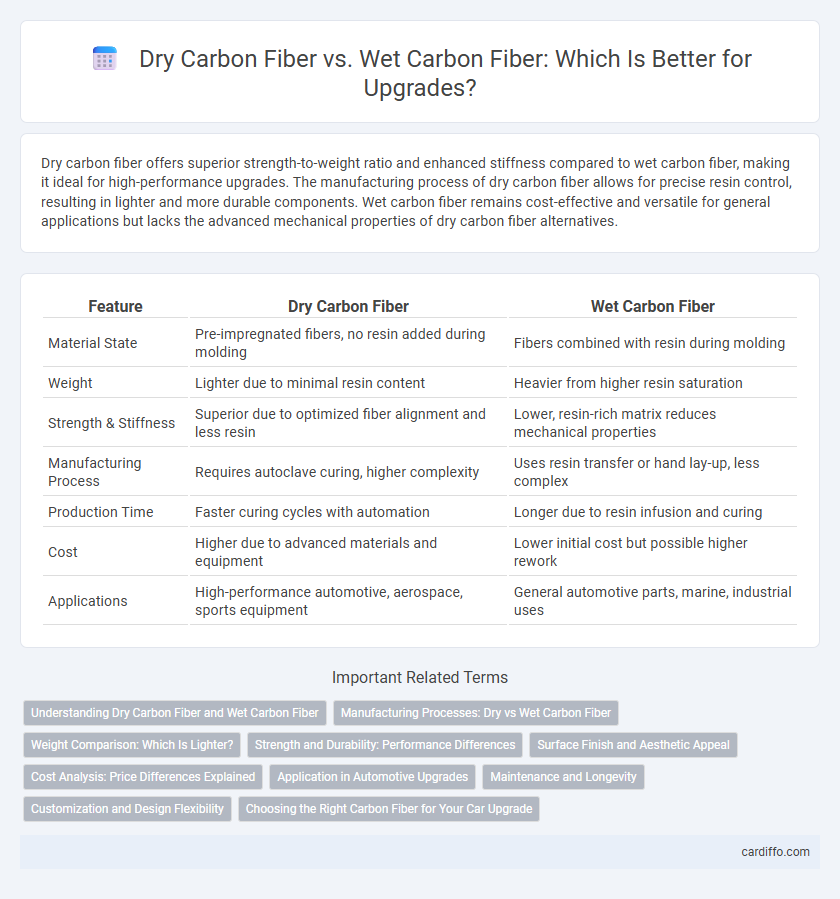

Table of Comparison

| Feature | Dry Carbon Fiber | Wet Carbon Fiber |

|---|---|---|

| Material State | Pre-impregnated fibers, no resin added during molding | Fibers combined with resin during molding |

| Weight | Lighter due to minimal resin content | Heavier from higher resin saturation |

| Strength & Stiffness | Superior due to optimized fiber alignment and less resin | Lower, resin-rich matrix reduces mechanical properties |

| Manufacturing Process | Requires autoclave curing, higher complexity | Uses resin transfer or hand lay-up, less complex |

| Production Time | Faster curing cycles with automation | Longer due to resin infusion and curing |

| Cost | Higher due to advanced materials and equipment | Lower initial cost but possible higher rework |

| Applications | High-performance automotive, aerospace, sports equipment | General automotive parts, marine, industrial uses |

Understanding Dry Carbon Fiber and Wet Carbon Fiber

Dry carbon fiber offers enhanced strength-to-weight ratio and improved resin control compared to wet carbon fiber, resulting in superior structural performance. Wet carbon fiber involves pre-impregnated fibers saturated with resin, which can lead to slight weight increases and less precise resin distribution. Understanding these material differences is essential for applications requiring optimized durability, weight savings, and manufacturing efficiency.

Manufacturing Processes: Dry vs Wet Carbon Fiber

Dry carbon fiber manufacturing involves pre-impregnated fibers cured under heat and pressure, resulting in superior fiber alignment and strength-to-weight ratio. Wet carbon fiber fabrication uses resin infusion into dry fabric, offering greater flexibility and lower initial cost but often less consistent fiber distribution. The choice between dry and wet processes impacts the structural performance, production time, and overall quality of carbon fiber composites.

Weight Comparison: Which Is Lighter?

Dry carbon fiber weighs significantly less than wet carbon fiber due to its high fiber content and minimal resin usage, resulting in a superior strength-to-weight ratio. Wet carbon fiber contains more resin, increasing its overall weight and slightly reducing its structural efficiency. Athletes and engineers often prefer dry carbon fiber for upgrades where weight reduction enhances performance and handling.

Strength and Durability: Performance Differences

Dry carbon fiber exhibits superior strength and durability compared to wet carbon fiber due to its higher fiber-to-resin ratio and reduced void content, which enhances load-bearing capacity and impact resistance. The autoclave curing process used in dry carbon fiber manufacturing ensures uniform resin distribution and optimal fiber alignment, resulting in a stiffer, more fatigue-resistant composite. In contrast, wet carbon fiber often contains more resin and air pockets, leading to lower mechanical performance and decreased lifespan under stress.

Surface Finish and Aesthetic Appeal

Dry carbon fiber offers a superior surface finish with a smoother, glossier appearance due to its high fiber-to-resin ratio, enhancing the aesthetic appeal of automotive and aerospace components. Wet carbon fiber typically has a less uniform surface with visible resin inconsistencies and a duller finish, resulting from excess resin absorption during the curing process. Choosing dry carbon fiber upgrades ensures sharper, more vibrant visual quality that meets premium design standards.

Cost Analysis: Price Differences Explained

Dry carbon fiber typically costs 20-30% more than wet carbon fiber due to its advanced manufacturing process and superior mechanical properties. Wet carbon fiber uses resin infusion methods, making it less expensive but resulting in heavier, less durable components. The higher initial investment in dry carbon fiber often leads to better long-term value for high-performance and aerospace applications.

Application in Automotive Upgrades

Dry carbon fiber offers superior strength-to-weight ratio and enhanced stiffness, making it ideal for high-performance automotive upgrades such as chassis components and body panels. Wet carbon fiber, while more flexible and cost-effective, is commonly used in interior trim and non-structural parts where intricate shapes and lower production costs are prioritized. The choice between dry and wet carbon fiber significantly impacts vehicle weight reduction, durability, and overall upgrade performance in motorsports and luxury automotive applications.

Maintenance and Longevity

Dry carbon fiber exhibits superior resistance to moisture absorption and environmental degradation compared to wet carbon fiber, resulting in lower maintenance requirements and enhanced durability. Its fully cured resin matrix minimizes the risk of delamination, extending the lifespan of components in high-performance applications. Wet carbon fiber, while more cost-effective initially, often requires more frequent inspections and repairs due to its susceptibility to water ingress and resin breakdown.

Customization and Design Flexibility

Dry carbon fiber offers superior customization and design flexibility due to its ability to be precisely laid up in complex shapes and varied fiber orientations, enabling tailored strength and stiffness in specific areas. Wet carbon fiber, limited by resin impregnation during the layup process, often restricts design complexity and results in less control over fiber alignment. The advanced control inherent in dry carbon fiber manufacturing supports innovative, lightweight structures optimized for high-performance applications.

Choosing the Right Carbon Fiber for Your Car Upgrade

Dry carbon fiber offers superior strength-to-weight ratio and stiffness compared to wet carbon fiber, making it ideal for high-performance car upgrades requiring maximum durability and lightweight components. Wet carbon fiber, while more cost-effective and easier to mold, is better suited for cosmetic or less structurally demanding parts due to its lower fiber alignment and resin content. Selecting between dry and wet carbon fiber depends on the balance between performance goals, budget constraints, and application-specific requirements in automotive upgrades.

Dry carbon fiber vs wet carbon fiber Infographic

cardiffo.com

cardiffo.com