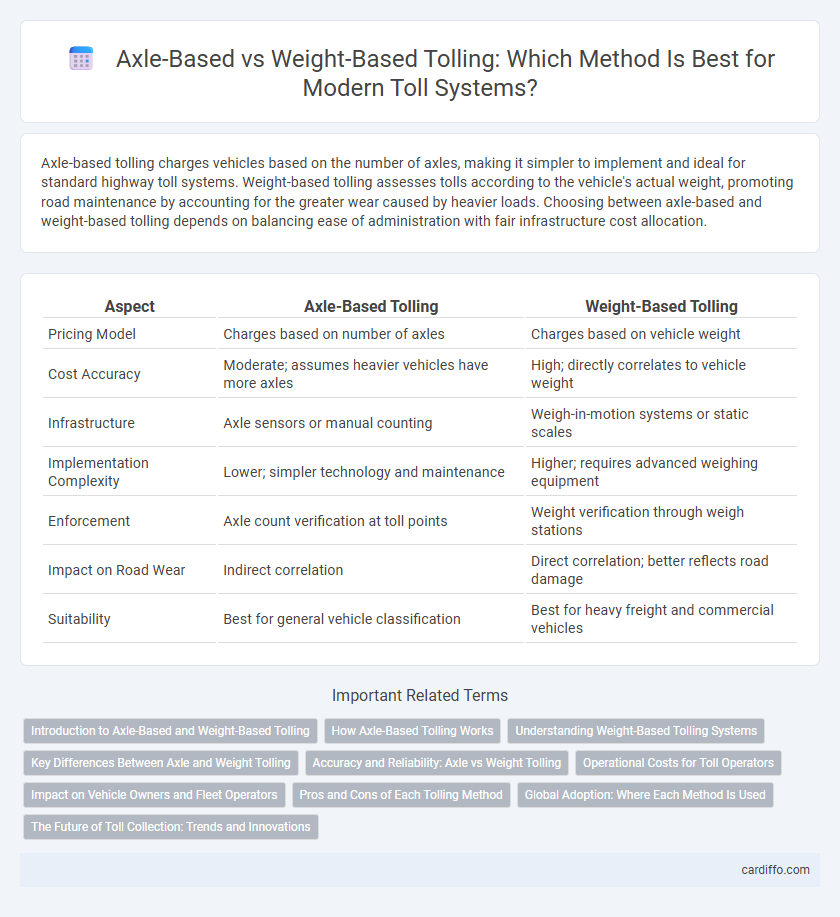

Axle-based tolling charges vehicles based on the number of axles, making it simpler to implement and ideal for standard highway toll systems. Weight-based tolling assesses tolls according to the vehicle's actual weight, promoting road maintenance by accounting for the greater wear caused by heavier loads. Choosing between axle-based and weight-based tolling depends on balancing ease of administration with fair infrastructure cost allocation.

Table of Comparison

| Aspect | Axle-Based Tolling | Weight-Based Tolling |

|---|---|---|

| Pricing Model | Charges based on number of axles | Charges based on vehicle weight |

| Cost Accuracy | Moderate; assumes heavier vehicles have more axles | High; directly correlates to vehicle weight |

| Infrastructure | Axle sensors or manual counting | Weigh-in-motion systems or static scales |

| Implementation Complexity | Lower; simpler technology and maintenance | Higher; requires advanced weighing equipment |

| Enforcement | Axle count verification at toll points | Weight verification through weigh stations |

| Impact on Road Wear | Indirect correlation | Direct correlation; better reflects road damage |

| Suitability | Best for general vehicle classification | Best for heavy freight and commercial vehicles |

Introduction to Axle-Based and Weight-Based Tolling

Axle-based tolling charges vehicles based on the number of axles, facilitating simple classification and fair toll distribution across diverse vehicle types. Weight-based tolling levies fees according to vehicle weight, targeting infrastructure wear and promoting improved road maintenance funding. Both systems aim to balance revenue fairness with infrastructure preservation, adapting to varying transportation policies and road usage patterns.

How Axle-Based Tolling Works

Axle-based tolling charges vehicles according to the number of axles, directly correlating toll rates with vehicle size and road impact. Sensors embedded in the road or overhead gantries detect axle counts as vehicles pass, enabling automatic fee calculation without stopping traffic flow. This method simplifies toll collection and ensures fairer charges by reflecting the roadway wear caused by larger, multi-axle vehicles.

Understanding Weight-Based Tolling Systems

Weight-based tolling systems charge vehicles based on their actual weight or axle load, improving road maintenance funding by linking toll fees to road wear directly caused by heavier vehicles. These systems utilize sophisticated weigh-in-motion (WIM) technology to measure vehicle weight dynamically without disrupting traffic flow. Weight-based tolling encourages compliance and reduces infrastructure damage by incentivizing lighter loads and enforcing weight limits more effectively than traditional axle-based tolling.

Key Differences Between Axle and Weight Tolling

Axle-based tolling charges vehicles according to the number of axles, offering simplicity and ease of enforcement, especially for passenger cars and light trucks. Weight-based tolling calculates fees based on the vehicle's gross weight, providing a more equitable system that links road wear and infrastructure maintenance costs directly to heavier vehicles, such as commercial trucks and freight carriers. Key differences include axle tolling's fixed rate per axle regardless of load versus weight tolling's variable rate reflecting actual vehicle mass, influencing toll revenue structure and infrastructure preservation strategies.

Accuracy and Reliability: Axle vs Weight Tolling

Axle-based tolling offers greater accuracy by directly counting vehicle axles, reducing errors in classification and toll calculation compared to weight-based systems that can fluctuate due to varying cargo loads. Weight-based tolling relies on sensors measuring axle loads, which may be affected by dynamic factors such as cargo distribution and vehicle speed, leading to occasional inconsistencies. The reliability of axle-based tolling systems typically results in fewer disputes and streamlined enforcement, enhancing overall tolling precision.

Operational Costs for Toll Operators

Axle-based tolling generally incurs lower operational costs for toll operators due to simpler vehicle classification systems and reduced need for specialized weighing equipment. Weight-based tolling demands more investment in advanced scales and frequent maintenance, increasing both initial setup and ongoing operational expenses. Choosing axle-based tolling can streamline toll collection processes, minimizing labor and technology costs while maintaining effective revenue management.

Impact on Vehicle Owners and Fleet Operators

Axle-based tolling directly affects vehicle owners and fleet operators by increasing costs for vehicles with more axles, incentivizing the use of smaller or fewer axles to reduce toll expenses. Weight-based tolling imposes fees proportional to the vehicle's gross weight, encouraging operators to optimize load distribution and minimize overweight trips to avoid higher charges. Both tolling methods influence fleet management strategies, operational costs, and route planning, with weight-based tolling often leading to better infrastructure preservation and more equitable cost allocation based on road usage intensity.

Pros and Cons of Each Tolling Method

Axle-based tolling offers a straightforward calculation method and is easier to implement but may not accurately reflect the road damage caused by heavier vehicles. Weight-based tolling provides a fairer cost distribution by charging according to vehicle weight, leading to more precise infrastructure maintenance funding, yet it requires complex measurement systems and higher operational costs. Choosing between axle-based and weight-based tolling depends on balancing simplicity and accuracy in toll revenue and road impact management.

Global Adoption: Where Each Method Is Used

Axle-based tolling is predominantly adopted in North America and Europe, where infrastructure and vehicle classifications align with axle count for toll calculation. Weight-based tolling sees greater use in regions like Australia and parts of Asia, reflecting a focus on road wear and freight impact. Both methods support efficient revenue collection but cater to different regulatory and logistical priorities worldwide.

The Future of Toll Collection: Trends and Innovations

Axle-based tolling offers efficient, scalable solutions for varying vehicle types by charging according to axle count, promoting equity in road usage fees. Weight-based tolling integrates advanced sensor technology to dynamically assess vehicle weight, ensuring tolls reflect infrastructure impact more accurately. Emerging trends include real-time data analytics and automated enforcement systems, driving innovations towards seamless, fair, and adaptive toll collection frameworks.

Axle-Based Tolling vs Weight-Based Tolling Infographic

cardiffo.com

cardiffo.com