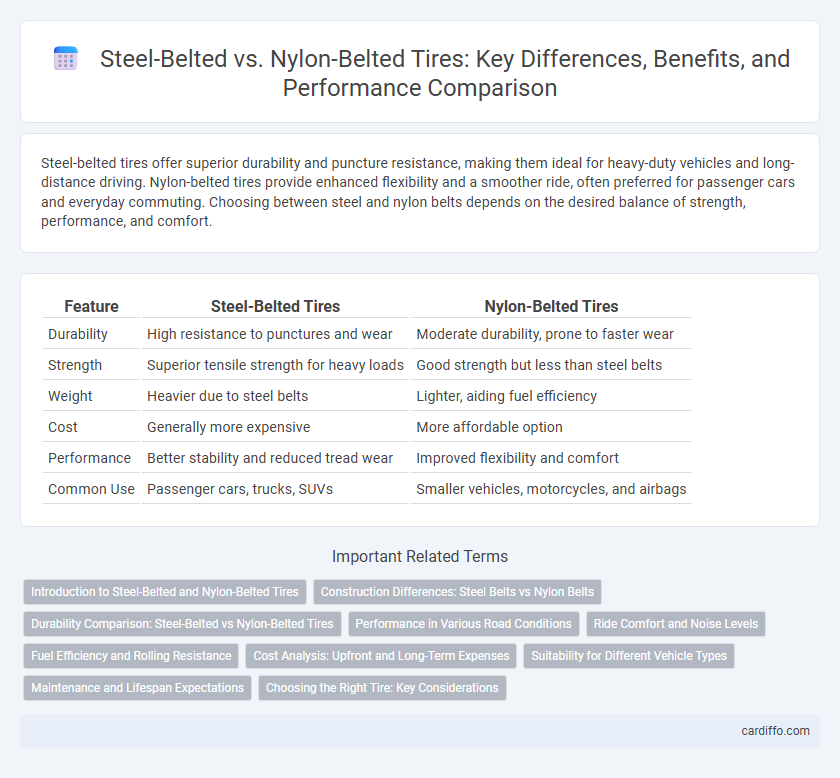

Steel-belted tires offer superior durability and puncture resistance, making them ideal for heavy-duty vehicles and long-distance driving. Nylon-belted tires provide enhanced flexibility and a smoother ride, often preferred for passenger cars and everyday commuting. Choosing between steel and nylon belts depends on the desired balance of strength, performance, and comfort.

Table of Comparison

| Feature | Steel-Belted Tires | Nylon-Belted Tires |

|---|---|---|

| Durability | High resistance to punctures and wear | Moderate durability, prone to faster wear |

| Strength | Superior tensile strength for heavy loads | Good strength but less than steel belts |

| Weight | Heavier due to steel belts | Lighter, aiding fuel efficiency |

| Cost | Generally more expensive | More affordable option |

| Performance | Better stability and reduced tread wear | Improved flexibility and comfort |

| Common Use | Passenger cars, trucks, SUVs | Smaller vehicles, motorcycles, and airbags |

Introduction to Steel-Belted and Nylon-Belted Tires

Steel-belted tires feature layers of steel cords embedded beneath the tread, providing enhanced strength, durability, and improved puncture resistance compared to traditional tires. Nylon-belted tires incorporate nylon fabric belts that offer flexibility, lighter weight, and better shock absorption, resulting in a smoother ride and improved handling. Both tire types are engineered to optimize performance and safety, with steel belts excelling in toughness and nylon belts enhancing comfort and agility.

Construction Differences: Steel Belts vs Nylon Belts

Steel-belted tires feature layers of steel cords embedded beneath the tread, providing enhanced durability, puncture resistance, and improved stability at high speeds. Nylon-belted tires use synthetic nylon fabric belts that offer flexibility, lighter weight, and better ride comfort but typically have lower resistance to road hazards compared to steel belts. The distinct construction difference lies in the materials and arrangement of reinforcing belts, with steel belts offering superior strength and nylon belts contributing to smoother handling.

Durability Comparison: Steel-Belted vs Nylon-Belted Tires

Steel-belted tires offer superior durability due to their enhanced resistance to punctures and tread wear, making them ideal for heavy-duty and high-speed applications. Nylon-belted tires, while providing flexibility and lighter weight, tend to have a shorter lifespan under extreme stress and rough road conditions. The steel belts maintain structural integrity longer, resulting in extended tire life and improved performance in durability-focused environments.

Performance in Various Road Conditions

Steel-belted tires offer superior durability and puncture resistance, making them ideal for highways and rough terrains with sharp debris. Nylon-belted tires provide enhanced flexibility and better traction on wet or icy roads due to their lighter, more pliable construction. Performance in varying conditions depends on tire composition, with steel belts excelling in stability and nylon belts improving grip and ride comfort.

Ride Comfort and Noise Levels

Steel-belted tires provide enhanced ride comfort by offering superior stability and durability, effectively reducing vibrations on rough roads. Nylon-belted tires contribute to quieter rides due to their flexible construction, which absorbs road noise more efficiently. Choosing between them depends on prioritizing either structural strength with moderate noise or optimal noise reduction with slightly less rigidity.

Fuel Efficiency and Rolling Resistance

Steel-belted tires typically offer lower rolling resistance compared to nylon-belted tires, contributing to better fuel efficiency by reducing the energy required to maintain motion. The rigid steel belts provide enhanced tire stability and durability, which minimizes deformation and energy loss during driving. Nylon-belted tires, while flexible and lightweight, generally exhibit higher rolling resistance, leading to increased fuel consumption.

Cost Analysis: Upfront and Long-Term Expenses

Steel-belted tires generally have a higher upfront cost due to more expensive raw materials and manufacturing processes. However, their durability and resistance to punctures often result in lower long-term expenses by reducing replacement frequency and maintenance costs. Nylon-belted tires may cost less initially but tend to wear out faster, potentially increasing overall tire-related expenditures over time.

Suitability for Different Vehicle Types

Steel-belted tires provide enhanced durability and puncture resistance, making them ideal for heavy-duty vehicles such as trucks and SUVs that require robust performance on rough terrains. Nylon-belted tires offer greater flexibility and comfort, suited for passenger cars and sports vehicles that benefit from improved ride quality and handling on paved roads. The choice between steel and nylon belts depends on vehicle weight, driving conditions, and desired tire performance characteristics.

Maintenance and Lifespan Expectations

Steel-belted tires offer enhanced durability and resistance to punctures, resulting in longer lifespans and less frequent maintenance compared to nylon-belted tires. Nylon-belted tires provide a smoother ride due to their flexibility but tend to wear out faster and require more frequent inspections for tread wear and alignment. Proper rotation, balancing, and maintaining the recommended air pressure significantly extend the lifespan of both tire types.

Choosing the Right Tire: Key Considerations

Steel-belted tires offer superior durability and puncture resistance, making them ideal for heavy loads and rough terrain. Nylon-belted tires provide enhanced flexibility and smoother rides, benefiting everyday driving and fuel efficiency. Key considerations include vehicle type, driving conditions, and performance needs to select the best tire belt material for safety and longevity.

Steel-belted tires vs Nylon-belted tires Infographic

cardiffo.com

cardiffo.com