Cross-ply tires feature layers of fabric cords arranged diagonally, offering enhanced sidewall flexibility and a smoother ride on rough surfaces. Steel-belted radial tires incorporate steel belts beneath the tread, providing superior durability, better fuel efficiency, and improved traction on highways. Choosing between cross-ply and steel-belted radial tires depends on the vehicle's use, with cross-ply favored for heavy loads and off-road conditions, while radial tires excel in everyday driving and long-distance travel.

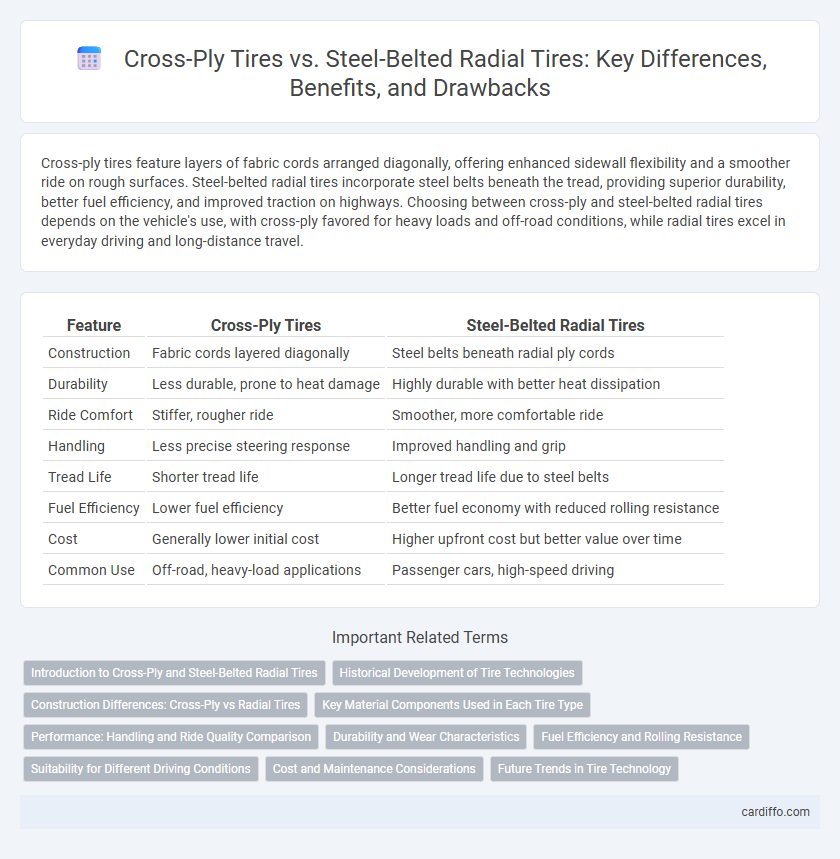

Table of Comparison

| Feature | Cross-Ply Tires | Steel-Belted Radial Tires |

|---|---|---|

| Construction | Fabric cords layered diagonally | Steel belts beneath radial ply cords |

| Durability | Less durable, prone to heat damage | Highly durable with better heat dissipation |

| Ride Comfort | Stiffer, rougher ride | Smoother, more comfortable ride |

| Handling | Less precise steering response | Improved handling and grip |

| Tread Life | Shorter tread life | Longer tread life due to steel belts |

| Fuel Efficiency | Lower fuel efficiency | Better fuel economy with reduced rolling resistance |

| Cost | Generally lower initial cost | Higher upfront cost but better value over time |

| Common Use | Off-road, heavy-load applications | Passenger cars, high-speed driving |

Introduction to Cross-Ply and Steel-Belted Radial Tires

Cross-ply tires feature layers of fabric cords placed at alternating angles to the tire centerline, offering flexibility and a smooth ride on rough roads. Steel-belted radial tires incorporate steel belts beneath the tread for enhanced durability, improved fuel efficiency, and better traction. These structural differences impact tire performance, longevity, and vehicle handling characteristics.

Historical Development of Tire Technologies

Cross-ply tires dominated early 20th-century vehicle performance by utilizing layered fabric plies arranged at alternating angles, providing durability but limiting flexibility and fuel efficiency. The introduction of steel-belted radial tires in the 1940s revolutionized tire technology with steel cords embedded beneath the tread, enhancing strength, traction, and tread life while improving fuel economy. This technological shift marked a significant advancement in automotive safety and performance, influencing modern tire manufacturing standards globally.

Construction Differences: Cross-Ply vs Radial Tires

Cross-ply tires feature multiple fabric plies layered diagonally across the tire, creating a flexible yet strong carcass, while steel-belted radial tires incorporate cords positioned at 90 degrees to the tread with steel belts beneath, enhancing durability and tread stability. This difference in ply orientation significantly impacts performance, with radial tires offering improved traction, longer tread life, and better fuel efficiency compared to the more flexible cross-ply design. Steel belts in radial tires also reduce heat buildup, contributing to safer high-speed driving and enhanced overall tire longevity.

Key Material Components Used in Each Tire Type

Cross-ply tires primarily utilize layers of polyester or nylon cords arranged at alternating angles, providing flexibility and resistance to punctures. Steel-belted radial tires incorporate steel belts beneath the tread for enhanced strength and durability, combined with polyester or fabric plies for improved ride comfort. The key material components in steel-belted radials result in better wear resistance and fuel efficiency compared to the more rigid structure of cross-ply tires.

Performance: Handling and Ride Quality Comparison

Cross-ply tires typically offer a stiffer sidewall, resulting in less flexible handling but more durability on rough terrains compared to steel-belted radial tires. Steel-belted radial tires provide superior handling with enhanced grip and smoother ride quality due to their construction, which allows for better road contact and shock absorption. This design reduces rolling resistance and improves fuel efficiency while delivering improved cornering stability and overall driving comfort.

Durability and Wear Characteristics

Cross-ply tires feature multiple layers of fabric cords crisscrossed at angles, providing enhanced sidewall strength but generally lower tread durability compared to steel-belted radial tires. Steel-belted radial tires incorporate steel belts beneath the tread, offering superior wear resistance, improved tread life, and consistent performance under various driving conditions. The radial construction allows for better heat dissipation and tread contact with the road, significantly extending the tire's overall lifespan.

Fuel Efficiency and Rolling Resistance

Steel-belted radial tires typically offer lower rolling resistance compared to cross-ply tires, resulting in improved fuel efficiency for vehicles. The radial construction allows the tire to maintain better road contact and reduce energy loss during rotation. Consequently, drivers using steel-belted radial tires often experience longer mileage per gallon of fuel and reduced carbon emissions.

Suitability for Different Driving Conditions

Cross-ply tires offer enhanced durability and flexibility, making them suitable for rough terrains and off-road driving conditions where sidewall strength is crucial. Steel-belted radial tires provide superior tread wear, fuel efficiency, and handling performance, making them ideal for highway and urban driving with smoother surfaces. The choice between cross-ply and radial tires depends on the specific demands of the driving environment, such as load capacity, road type, and driving speed.

Cost and Maintenance Considerations

Cross-ply tires generally cost less upfront compared to steel-belted radial tires, making them a budget-friendly choice for cost-conscious drivers. Maintenance for cross-ply tires tends to be more frequent due to faster wear and lower durability, whereas steel-belted radial tires, although initially more expensive, offer longer tread life and reduced maintenance needs. Choosing between the two depends on balancing initial purchase cost against long-term savings from tire longevity and fewer maintenance interventions.

Future Trends in Tire Technology

Cross-ply tires, known for their layered fabric construction, are gradually being supplanted by steel-belted radial tires due to superior durability and fuel efficiency. Future trends in tire technology emphasize advanced radial designs incorporating smart sensors for real-time monitoring of tire pressure, temperature, and tread wear. Innovations in materials such as sustainable rubber compounds and self-healing properties are set to enhance the performance and environmental impact of steel-belted radial tires.

Cross-ply tires vs steel-belted radial tires Infographic

cardiffo.com

cardiffo.com