Mesh wheels offer a stylish, intricate design with multiple spokes that enhance vehicle aesthetics and provide reasonable strength at a lower cost. Forged wheels are crafted from a single block of alloy, resulting in superior strength, reduced weight, and better performance under high stress, ideal for aggressive driving and racing. Choosing between mesh and forged wheels depends on balancing budget, visual preference, and performance needs for your modified vehicle.

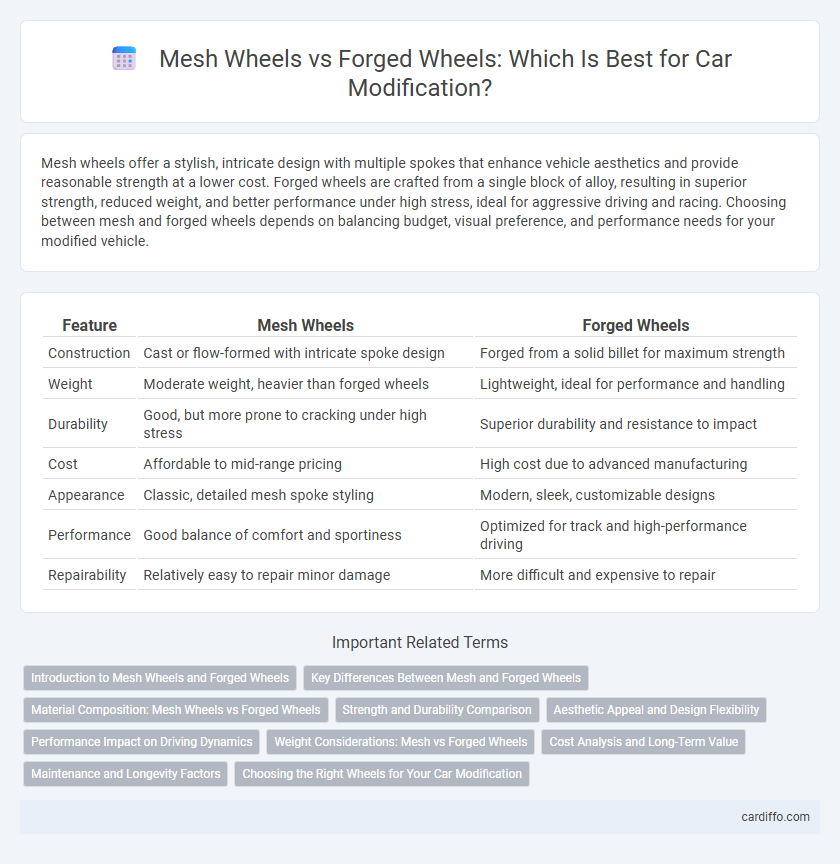

Table of Comparison

| Feature | Mesh Wheels | Forged Wheels |

|---|---|---|

| Construction | Cast or flow-formed with intricate spoke design | Forged from a solid billet for maximum strength |

| Weight | Moderate weight, heavier than forged wheels | Lightweight, ideal for performance and handling |

| Durability | Good, but more prone to cracking under high stress | Superior durability and resistance to impact |

| Cost | Affordable to mid-range pricing | High cost due to advanced manufacturing |

| Appearance | Classic, detailed mesh spoke styling | Modern, sleek, customizable designs |

| Performance | Good balance of comfort and sportiness | Optimized for track and high-performance driving |

| Repairability | Relatively easy to repair minor damage | More difficult and expensive to repair |

Introduction to Mesh Wheels and Forged Wheels

Mesh wheels feature an intricate network of spokes forming a web-like pattern, offering a balance of lightweight design and structural strength ideal for performance vehicles. Forged wheels are crafted from a single block of metal using high-pressure forging, resulting in superior durability, reduced weight, and enhanced resistance to impact. Both wheel types cater to automotive enthusiasts seeking optimized performance and aesthetic appeal, with mesh wheels providing a classic multi-spoke look and forged wheels delivering cutting-edge strength and weight benefits.

Key Differences Between Mesh and Forged Wheels

Mesh wheels feature a complex web-like design offering enhanced aesthetic appeal and improved brake cooling due to increased airflow, while forged wheels are constructed from a single block of aluminum using a high-pressure forging process, resulting in superior strength and reduced weight. Mesh wheels tend to be heavier and less durable under extreme stress compared to forged wheels, which provide better performance and longevity in high-performance or racing applications. The choice between mesh and forged wheels depends on priorities such as visual style, weight savings, and structural integrity.

Material Composition: Mesh Wheels vs Forged Wheels

Mesh wheels are typically made from cast aluminum alloys, offering a balance of affordability and strength through a multi-spoke design that distributes stress efficiently. Forged wheels utilize a solid billet of high-grade aluminum alloy, subjected to intense heat and pressure, resulting in a denser, stronger, and lighter structure. The superior material density in forged wheels translates to enhanced durability and performance under extreme driving conditions compared to the more porous cast composition of mesh wheels.

Strength and Durability Comparison

Forged wheels exhibit superior strength and durability compared to mesh wheels due to their manufacturing process, which involves compressing molten aluminum under high pressure to create a dense, solid structure. Mesh wheels, typically cast from molten metal poured into molds, are more prone to cracking or bending under extreme stress. The enhanced grain structure of forged wheels provides better resistance to impact and fatigue, making them ideal for high-performance and off-road applications.

Aesthetic Appeal and Design Flexibility

Mesh wheels offer a intricate, multi-spoke design that enhances a vehicle's aesthetic appeal with a classic and detailed look, often favored for vintage and luxury cars. Forged wheels provide greater design flexibility due to their manufacturing process, allowing for unique shapes, thinner spokes, and lighter weight without compromising strength, which appeals to enthusiasts seeking a modern and aggressive style. Both wheel types significantly impact the visual character of a vehicle, with mesh wheels emphasizing elegance and forged wheels highlighting custom, performance-oriented designs.

Performance Impact on Driving Dynamics

Forged wheels offer superior rigidity and reduced weight compared to mesh wheels, significantly enhancing acceleration, braking, and cornering performance. The increased strength of forged wheels improves handling responsiveness by minimizing flex under high stress, which is essential for dynamic driving conditions. Mesh wheels, while stylish and lightweight, typically lack the structural benefits of forged wheels, resulting in less optimized driving dynamics for performance-focused applications.

Weight Considerations: Mesh vs Forged Wheels

Forged wheels offer significant weight advantages over mesh wheels due to their manufacturing process, which involves compressing a solid alloy billet under high pressure, resulting in a denser and lighter structure. Mesh wheels, often cast or flow-formed, tend to be heavier because their intricate design and production methods add extra material for strength, increasing unsprung mass. Reduced weight in forged wheels improves acceleration, braking, and handling by lowering rotational inertia and enhancing suspension response.

Cost Analysis and Long-Term Value

Mesh wheels generally offer a lower initial cost compared to forged wheels, making them an attractive option for budget-conscious car enthusiasts. Forged wheels provide superior strength and durability, resulting in longer lifespan and better performance, which can lead to reduced replacement and maintenance costs over time. Evaluating long-term value, forged wheels often deliver greater return on investment through enhanced safety, weight savings, and resistance to damage despite higher upfront expenses.

Maintenance and Longevity Factors

Mesh wheels often require more frequent maintenance due to their intricate spoke design, which can trap dirt and debris, leading to corrosion and damage over time. Forged wheels, made from a single piece of metal, offer superior strength and durability, resulting in longer lifespan and reduced risk of cracks or bends under stress. Regular inspection and cleaning are essential for mesh wheels to maintain performance, whereas forged wheels generally demand less upkeep while ensuring consistent structural integrity.

Choosing the Right Wheels for Your Car Modification

Choosing the right wheels for your car modification depends on factors like performance, weight, and aesthetics. Mesh wheels offer a classic design with moderate weight and durability, ideal for street tuning and casual driving. Forged wheels provide superior strength and lighter weight, enhancing handling and acceleration, making them the preferred choice for high-performance and track applications.

mesh wheels vs forged wheels Infographic

cardiffo.com

cardiffo.com