Carbon fiber offers superior strength-to-weight ratio compared to fiberglass, making it ideal for high-performance pet modifications requiring durability and lightweight materials. Fiberglass is more cost-effective and easier to mold into complex shapes, suited for budget-friendly, custom pet accessories. Choosing between carbon fiber and fiberglass depends on balancing performance needs and budget constraints in pet modifications.

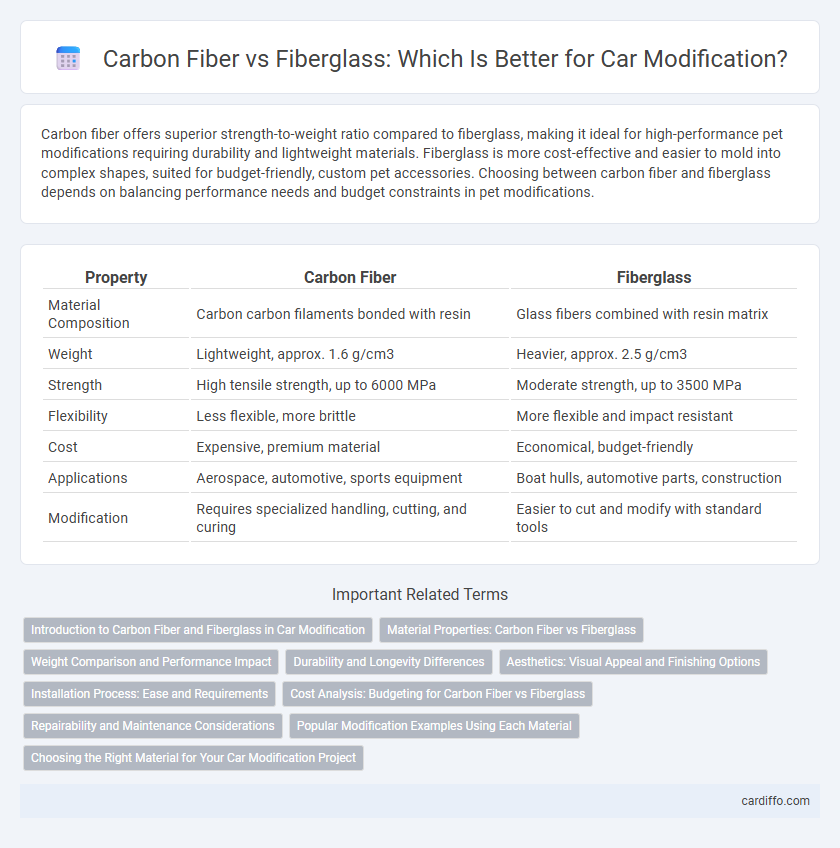

Table of Comparison

| Property | Carbon Fiber | Fiberglass |

|---|---|---|

| Material Composition | Carbon carbon filaments bonded with resin | Glass fibers combined with resin matrix |

| Weight | Lightweight, approx. 1.6 g/cm3 | Heavier, approx. 2.5 g/cm3 |

| Strength | High tensile strength, up to 6000 MPa | Moderate strength, up to 3500 MPa |

| Flexibility | Less flexible, more brittle | More flexible and impact resistant |

| Cost | Expensive, premium material | Economical, budget-friendly |

| Applications | Aerospace, automotive, sports equipment | Boat hulls, automotive parts, construction |

| Modification | Requires specialized handling, cutting, and curing | Easier to cut and modify with standard tools |

Introduction to Carbon Fiber and Fiberglass in Car Modification

Carbon fiber offers superior strength-to-weight ratio and stiffness compared to fiberglass, making it ideal for performance car modifications requiring lightweight durability. Fiberglass remains popular for cost-effective body panels and custom parts due to its ease of shaping and affordability. Both materials are widely used in automotive modification, with carbon fiber favored in high-performance applications and fiberglass common in hobbyist and budget builds.

Material Properties: Carbon Fiber vs Fiberglass

Carbon fiber exhibits superior tensile strength and stiffness compared to fiberglass, making it ideal for applications requiring high performance and lightweight materials. Fiberglass offers greater flexibility and impact resistance, providing enhanced durability in environments prone to shocks and vibrations. Both materials demonstrate excellent corrosion resistance, but carbon fiber outperforms fiberglass in fatigue resistance and thermal stability, influencing their selection in structural modifications.

Weight Comparison and Performance Impact

Carbon fiber weighs approximately 1.6 grams per cubic centimeter, making it significantly lighter than fiberglass, which weighs around 2.5 grams per cubic centimeter. This 36% reduction in weight translates to improved acceleration, handling, and fuel efficiency in performance applications ranging from automotive to aerospace. The higher stiffness-to-weight ratio of carbon fiber enhances structural integrity while maintaining low mass, providing superior performance impact over fiberglass in weight-sensitive modifications.

Durability and Longevity Differences

Carbon fiber exhibits superior durability compared to fiberglass due to its higher tensile strength and resistance to fatigue, making it ideal for high-performance applications requiring long-lasting materials. Fiberglass, while less expensive, tends to degrade faster under prolonged stress and environmental exposure, resulting in reduced longevity. The inherent structural integrity of carbon fiber allows for extended service life in demanding conditions where fiberglass may fail or require frequent replacement.

Aesthetics: Visual Appeal and Finishing Options

Carbon fiber offers a sleek, high-tech appearance with a distinctive woven pattern that enhances the visual appeal of any modification project, often preferred for its modern and luxurious finish. Fiberglass provides a smoother surface that can be easily molded and painted, allowing for a wide variety of custom finishes and vibrant color options. Both materials support diverse aesthetic customization, but carbon fiber's inherent texture and sheen deliver a more premium, performance-oriented look.

Installation Process: Ease and Requirements

Carbon fiber installation demands precise surface preparation and specialized curing equipment, resulting in longer setup times and higher technical skill requirements compared to fiberglass. Fiberglass is generally easier to install with more flexible curing conditions and common materials that reduce labor intensity. This distinction impacts project timelines and labor costs in modification tasks.

Cost Analysis: Budgeting for Carbon Fiber vs Fiberglass

Carbon fiber offers superior strength-to-weight ratio but comes with a significantly higher price tag, often costing 3 to 5 times more than fiberglass. Fiberglass remains the budget-friendly option for modifications, with prices roughly $5 to $15 per square foot compared to carbon fiber's $20 to $50 per square foot. Considering long-term value, carbon fiber reduces maintenance costs due to its durability, while fiberglass requires frequent repairs, impacting overall budgeting.

Repairability and Maintenance Considerations

Carbon fiber exhibits superior strength-to-weight ratio but requires specialized repair techniques involving precise resin matching and carbon layering, making maintenance more complex and costly. Fiberglass, while less strong, offers easier and more affordable repair options with common materials like polyester resin and fiberglass cloth, allowing for straightforward patching and sanding. Maintenance of fiberglass is generally simpler due to its flexibility and tolerance to minor damages without compromising structural integrity.

Popular Modification Examples Using Each Material

Carbon fiber is predominantly used in high-performance automotive modifications such as lightweight body panels, aerodynamic components, and structural reinforcements due to its superior strength-to-weight ratio and stiffness. Fiberglass remains popular for custom body kits, fender flares, and interior trim pieces, offering an affordable and easily moldable option for both cosmetic and functional upgrades. Both materials are chosen based on the desired balance between cost, durability, and weight reduction in vehicle customization projects.

Choosing the Right Material for Your Car Modification Project

Carbon fiber offers superior strength-to-weight ratio and enhanced rigidity, making it ideal for high-performance car modification projects that demand lightweight durability. Fiberglass provides a cost-effective and easy-to-mold alternative, suitable for custom body panels and aesthetic enhancements without significantly increasing vehicle weight. Selecting the appropriate material depends on budget, desired strength, weight reduction goals, and the specific performance demands of the modification.

carbon fiber vs fiberglass Infographic

cardiffo.com

cardiffo.com