Bolt-on mods offer a straightforward upgrade by attaching pre-made parts to a vehicle for improved performance or aesthetics, requiring minimal customization. Fabrication mods involve custom-building components tailored to specific needs, allowing for more unique and precise enhancements but demanding advanced skills and tools. Choosing between bolt-on and fabrication mods depends on factors like budget, desired performance gains, and the level of personalization sought.

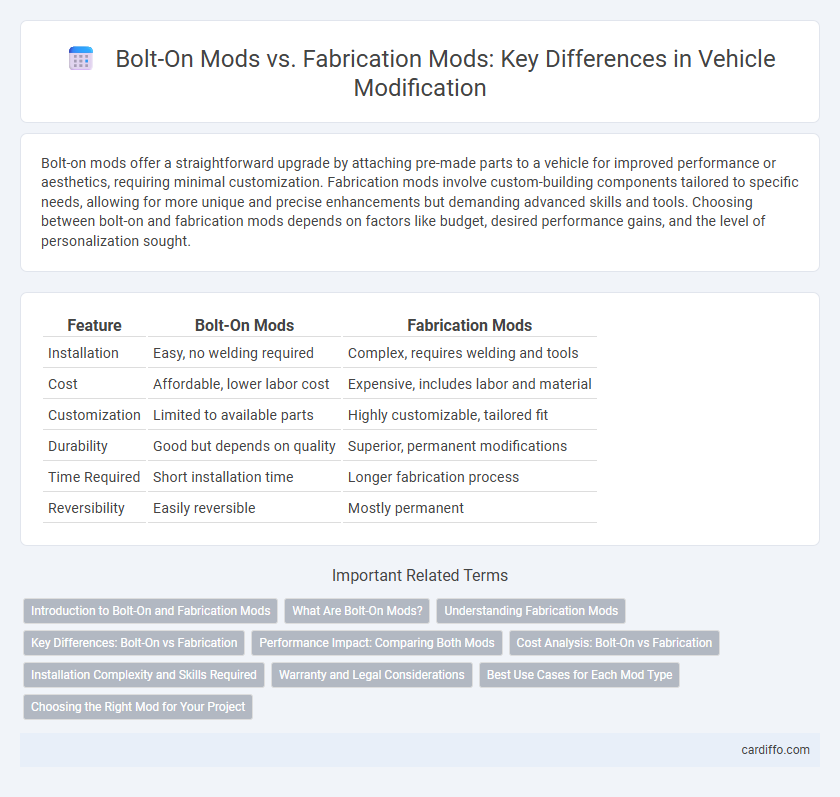

Table of Comparison

| Feature | Bolt-On Mods | Fabrication Mods |

|---|---|---|

| Installation | Easy, no welding required | Complex, requires welding and tools |

| Cost | Affordable, lower labor cost | Expensive, includes labor and material |

| Customization | Limited to available parts | Highly customizable, tailored fit |

| Durability | Good but depends on quality | Superior, permanent modifications |

| Time Required | Short installation time | Longer fabrication process |

| Reversibility | Easily reversible | Mostly permanent |

Introduction to Bolt-On and Fabrication Mods

Bolt-on mods refer to aftermarket parts that can be easily installed without altering the vehicle's original structure, such as cold air intakes, exhaust systems, and suspension upgrades. Fabrication mods involve custom-built components requiring modification or replacement of existing parts to achieve performance or aesthetic goals, commonly seen in roll cages or custom bumpers. Understanding the distinction helps enthusiasts choose between quick upgrades and more complex, tailored modifications.

What Are Bolt-On Mods?

Bolt-on mods are aftermarket parts that can be easily installed without altering the vehicle's original structure, such as cold air intakes, exhaust systems, and suspension components. These modifications improve performance, aesthetics, and functionality while maintaining the integrity of the factory design. Popular among automotive enthusiasts, bolt-on mods offer a straightforward, cost-effective way to customize vehicles with minimal mechanical skills.

Understanding Fabrication Mods

Fabrication mods involve custom-building parts or structures from raw materials, offering tailored solutions that bolt-on mods cannot achieve. These modifications require advanced skills in welding, cutting, and design to enhance vehicle performance or aesthetics uniquely. Understanding fabrication mods is crucial for drivers seeking personalized and functional upgrades beyond standard bolt-on options.

Key Differences: Bolt-On vs Fabrication

Bolt-on mods primarily involve attaching pre-manufactured parts to a vehicle, ensuring easy installation and reversibility without major structural changes. Fabrication mods require custom-building or altering components, offering greater customization but demanding advanced skills and more time. Key differences include the complexity of installation, cost, and the potential impact on vehicle integrity and warranty.

Performance Impact: Comparing Both Mods

Bolt-on modifications, such as cold air intakes and performance exhaust systems, provide immediate and measurable improvements in engine performance by increasing airflow and reducing backpressure without altering the vehicle's core structure. Fabrication mods, including custom turbo setups and engine swaps, deliver more significant power gains but require extensive mechanical changes and higher investment, often affecting reliability and drivability. Evaluating the performance impact involves balancing the ease of installation and consistent gains of bolt-ons against the transformative but complex enhancements of fabrication mods.

Cost Analysis: Bolt-On vs Fabrication

Bolt-on modifications typically cost less upfront, ranging from $200 to $1,500 depending on parts and complexity, while fabrication mods often exceed $2,000 due to custom labor and materials. Bolt-on mods offer quicker installation and easier upgrades, reducing labor expenses compared to time-intensive fabrication that requires specialized skills and tools. Total cost-effectiveness depends on project scope, with bolt-ons favored for budget-conscious builds and fabrication preferred for unique, high-performance customizations.

Installation Complexity and Skills Required

Bolt-on modifications offer straightforward installation with minimal tools, making them suitable for enthusiasts with basic mechanical skills. Fabrication modifications demand advanced technical knowledge, welding proficiency, and precise measurements, often requiring professional expertise. The complexity of fabrication mods significantly increases installation time and the need for specialized equipment compared to bolt-on alternatives.

Warranty and Legal Considerations

Bolt-on modifications typically maintain the vehicle's factory warranty as they are reversible and do not alter the core structure, whereas fabrication mods often void warranties due to permanent changes and potential safety risks. Legally, bolt-on mods usually comply with road regulations since they attach externally without affecting emissions or safety systems, while fabrication mods may face scrutiny or require inspections to meet local laws. Owners must carefully review warranty terms and regional regulations before opting for fabrication mods to avoid voided coverage or legal issues.

Best Use Cases for Each Mod Type

Bolt-on mods are ideal for enthusiasts seeking quick performance gains and easy installation without altering the vehicle's core structure, commonly used for upgrades like intake systems, exhausts, and suspension components. Fabrication mods are best suited for custom projects requiring significant structural changes or unique designs, such as roll cages, custom bumpers, or engine swaps, offering maximum flexibility and durability. Choosing between bolt-on and fabrication modifications depends on the desired level of customization, performance goals, and budget constraints.

Choosing the Right Mod for Your Project

Bolt-on modifications offer straightforward installation and maintain factory integrity, ideal for quick performance upgrades without extensive vehicle changes. Fabrication mods provide custom solutions tailored to unique project goals, allowing for enhanced strength and personalized fit but require specialized skills and more time. Evaluating project scope, budget, and desired outcome helps determine whether convenience or customization best suits your modification needs.

Bolt-on mods vs Fabrication mods Infographic

cardiffo.com

cardiffo.com