Rotary polishing delivers powerful, high-speed rotation that effectively removes deep scratches and oxidation, making it ideal for experienced users seeking aggressive paint correction. Dual action polishing combines oscillating and rotary movements to minimize heat build-up and reduce the risk of paint damage, providing a safer option for beginners and light polishing tasks. Choosing between rotary and dual action polishing depends on the level of paint correction required and the user's skill level to achieve optimal cleaning and polishing results.

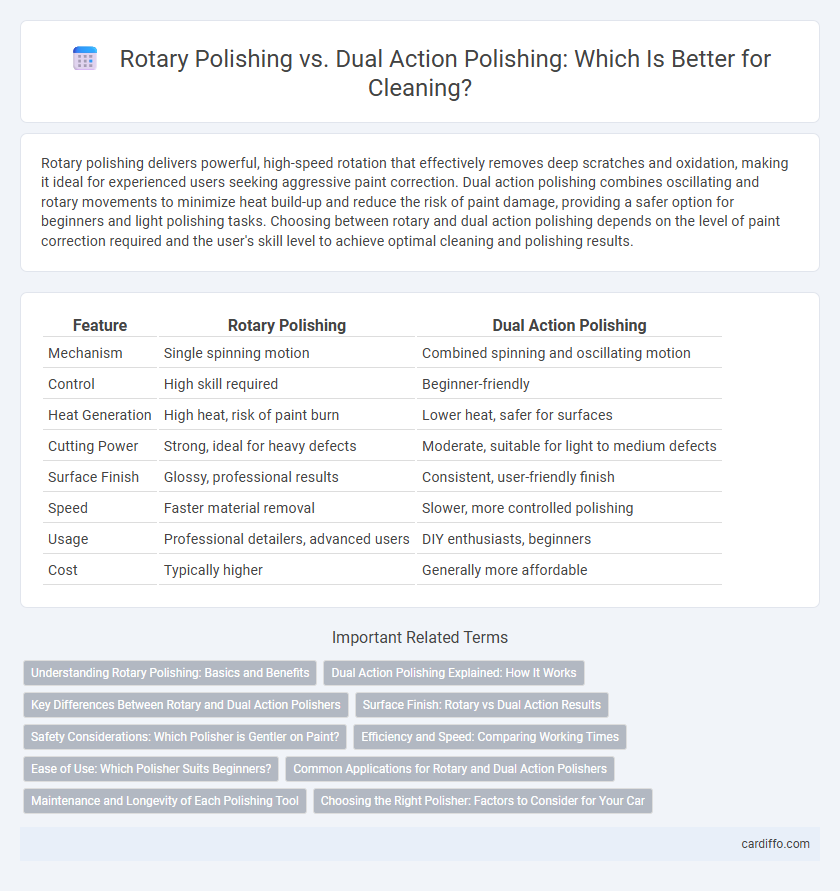

Table of Comparison

| Feature | Rotary Polishing | Dual Action Polishing |

|---|---|---|

| Mechanism | Single spinning motion | Combined spinning and oscillating motion |

| Control | High skill required | Beginner-friendly |

| Heat Generation | High heat, risk of paint burn | Lower heat, safer for surfaces |

| Cutting Power | Strong, ideal for heavy defects | Moderate, suitable for light to medium defects |

| Surface Finish | Glossy, professional results | Consistent, user-friendly finish |

| Speed | Faster material removal | Slower, more controlled polishing |

| Usage | Professional detailers, advanced users | DIY enthusiasts, beginners |

| Cost | Typically higher | Generally more affordable |

Understanding Rotary Polishing: Basics and Benefits

Rotary polishing utilizes a high-speed spinning pad to deliver intense, direct abrasion, effectively removing deep scratches and oxidation from paint surfaces. Its consistent, powerful motion allows for faster correction and a high-gloss finish, making it ideal for experienced users seeking professional-level results. Mastery of rotary polishing requires skill to avoid paint damage, but it offers unmatched efficiency in restoring severely marred automotive finishes.

Dual Action Polishing Explained: How It Works

Dual Action Polishing utilizes a unique elliptical motion combining rotation and oscillation, which reduces the risk of paint damage and swirl marks during vehicle detailing. This method ensures even product distribution and enhances the effectiveness of cleaning agents by preventing excessive heat buildup on the surface. Its user-friendly design makes it ideal for both beginners and professionals seeking a safer polishing experience with consistent results.

Key Differences Between Rotary and Dual Action Polishers

Rotary polishers feature a single spinning head that delivers high-speed, direct surface contact ideal for heavy paint correction, while dual action polishers combine orbital and rotary motions to minimize heat buildup and reduce the risk of paint damage. Rotary machines provide aggressive polishing with faster results but require advanced skill to prevent swirl marks, whereas dual action polishers offer a safer, user-friendly experience suited for beginners and intermediate users. The key differences lie in the motor action, heat generation, and suitability for varying skill levels and paint conditions.

Surface Finish: Rotary vs Dual Action Results

Rotary polishing delivers a high-gloss, mirror-like surface finish due to its consistent and aggressive single-direction rotation, making it ideal for removing deep scratches and oxidation. Dual action polishing produces a swirl-free, smooth surface that minimizes the risk of paint damage by combining orbital and rotational movement, resulting in a more evenly refined finish. The choice impacts surface quality; rotary machines excel in correction power, while dual action polishers prioritize safety and uniformity in finish.

Safety Considerations: Which Polisher is Gentler on Paint?

Rotary polishing generates high heat and fast spinning, increasing the risk of paint burns and clear coat damage, especially for beginners. Dual action (DA) polishing uses an oscillating motion that reduces friction and heat buildup, making it significantly gentler and safer for delicate automotive paint surfaces. Vehicle detailers prioritize DA polishers for paint protection and minimizing swirl marks during the polishing process.

Efficiency and Speed: Comparing Working Times

Rotary polishing delivers faster results by using a single rotating motion that aggressively removes imperfections, making it ideal for experienced users aiming for efficiency. Dual action polishing operates with combined orbital and rotary motions, providing a safer, swirl-free finish but generally requires more time to complete the job. Choosing between the two depends on the balance between speed and finishing quality, with rotary polishers outperforming in working time efficiency.

Ease of Use: Which Polisher Suits Beginners?

Dual action polishers offer greater ease of use for beginners due to their balanced, less aggressive motion that reduces the risk of paint damage. Rotary polishers require more skill, as their high-speed single-direction spinning can easily cause swirls or burns if mishandled. For novice users, dual action polishers provide a user-friendly experience with effective polishing results and improved safety.

Common Applications for Rotary and Dual Action Polishers

Rotary polishers are commonly used for heavy paint correction, removing deep scratches, oxidation, and severe swirl marks on automotive surfaces. Dual action polishers excel in lighter polishing tasks, such as enhancing gloss, removing minor imperfections, and applying wax or sealants safely without risking paint damage. Both tools are essential in professional detailing, catering to varying levels of paint correction and finishing needs.

Maintenance and Longevity of Each Polishing Tool

Rotary polishing machines offer powerful, high-speed rotation that effectively removes imperfections but require frequent maintenance due to wear on bearings and brushes, impacting tool longevity. Dual action polishers combine rotary and orbital motions, reducing heat buildup and surface damage, which extends the lifespan of polishing pads and minimizes tool maintenance. Proper upkeep of both tools, including regular cleaning and lubrication, significantly enhances performance durability and operational efficiency.

Choosing the Right Polisher: Factors to Consider for Your Car

Selecting the ideal polisher for your car involves evaluating factors such as paint condition, skill level, and desired finish. Rotary polishers provide powerful, high-speed rotation suitable for correcting severe paint imperfections but demand experienced handling to avoid damage. Dual action polishers offer a safer, user-friendly option with orbital motion that reduces the risk of swirls, making them ideal for beginners and regular maintenance.

Rotary Polishing vs Dual Action Polishing Infographic

cardiffo.com

cardiffo.com