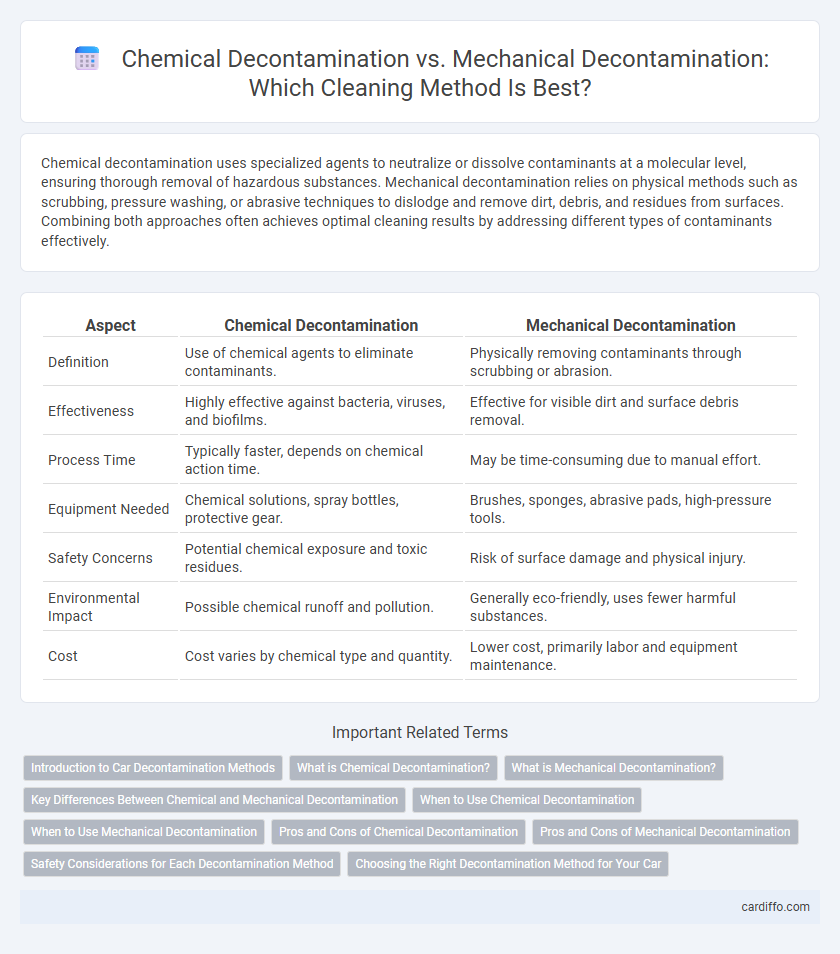

Chemical decontamination uses specialized agents to neutralize or dissolve contaminants at a molecular level, ensuring thorough removal of hazardous substances. Mechanical decontamination relies on physical methods such as scrubbing, pressure washing, or abrasive techniques to dislodge and remove dirt, debris, and residues from surfaces. Combining both approaches often achieves optimal cleaning results by addressing different types of contaminants effectively.

Table of Comparison

| Aspect | Chemical Decontamination | Mechanical Decontamination |

|---|---|---|

| Definition | Use of chemical agents to eliminate contaminants. | Physically removing contaminants through scrubbing or abrasion. |

| Effectiveness | Highly effective against bacteria, viruses, and biofilms. | Effective for visible dirt and surface debris removal. |

| Process Time | Typically faster, depends on chemical action time. | May be time-consuming due to manual effort. |

| Equipment Needed | Chemical solutions, spray bottles, protective gear. | Brushes, sponges, abrasive pads, high-pressure tools. |

| Safety Concerns | Potential chemical exposure and toxic residues. | Risk of surface damage and physical injury. |

| Environmental Impact | Possible chemical runoff and pollution. | Generally eco-friendly, uses fewer harmful substances. |

| Cost | Cost varies by chemical type and quantity. | Lower cost, primarily labor and equipment maintenance. |

Introduction to Car Decontamination Methods

Chemical decontamination involves the use of specialized cleaning agents designed to dissolve and remove contaminants such as brake dust, road grime, and industrial fallout from a vehicle's surface. Mechanical decontamination utilizes physical tools like clay bars, brushes, or abrasive pads to lift and scrape off embedded particles that chemical agents cannot fully eliminate. Combining both methods optimizes the overall cleanliness and preparation of the car's paintwork for waxing or sealing.

What is Chemical Decontamination?

Chemical decontamination involves the use of specific chemical agents to neutralize, remove, or destroy hazardous contaminants on surfaces, equipment, or environments. This method targets contaminants at a molecular level, breaking down toxic substances such as bacteria, viruses, and industrial residues through oxidation, reduction, or hydrolysis processes. Widely used in medical, industrial, and environmental settings, chemical decontamination ensures thorough sterilization and contamination control where mechanical methods alone may be insufficient.

What is Mechanical Decontamination?

Mechanical decontamination involves the physical removal of contaminants from surfaces using methods such as scrubbing, brushing, or high-pressure water jets. This technique is effective for dislodging dirt, debris, and biofilms without relying on chemical agents. It is often used in environments where chemical residues must be avoided or where rapid surface cleaning is required.

Key Differences Between Chemical and Mechanical Decontamination

Chemical decontamination involves the use of specific reagents, such as detergents, solvents, or disinfectants, to break down or neutralize contaminants on surfaces or equipment. Mechanical decontamination relies on physical methods like scrubbing, brushing, or high-pressure washing to remove dirt, debris, and biofilms without altering the chemical structure of the contaminants. Key differences include the efficacy against different types of contaminants, potential material compatibility issues in chemical decontamination, and the labor intensity or equipment requirement associated with mechanical methods.

When to Use Chemical Decontamination

Chemical decontamination is essential for removing hazardous substances such as biological agents, heavy metals, and toxic chemicals that mechanical methods cannot adequately address. It is best used in environments where contaminants are chemically bonded to surfaces or embedded in materials, requiring reactive solutions to neutralize or break down harmful compounds. This method proves critical in healthcare settings, industrial spills, and hazardous waste management where thorough microbial and chemical eradication is mandatory for safety and compliance.

When to Use Mechanical Decontamination

Mechanical decontamination is ideal for removing heavy soil, debris, and biofilms where chemical agents may be ineffective or cause damage to sensitive surfaces. This method is preferred in healthcare settings for sterilizing surgical instruments and medical devices that can withstand physical scrubbing or ultrasonic cleaning. Mechanical decontamination reduces reliance on harsh chemicals, minimizing risks of chemical residues and environmental impact.

Pros and Cons of Chemical Decontamination

Chemical decontamination effectively eliminates hazardous substances by breaking down contaminants at a molecular level, offering thorough disinfection and sterilization. However, it involves risks such as chemical exposure, potential environmental harm, and the need for specialized handling and disposal procedures. The process can also be time-consuming and costly compared to mechanical methods, limiting its practicality for frequent or large-scale cleaning tasks.

Pros and Cons of Mechanical Decontamination

Mechanical decontamination offers the advantage of physically removing contaminants without the use of harsh chemicals, reducing environmental impact and chemical exposure risks for workers. It is effective for large surface areas and can be more cost-efficient in the long term, but may require specialized equipment and higher energy consumption. However, mechanical methods may not fully eliminate microscopic or chemically bonded residues, limiting their efficacy compared to chemical decontamination in certain applications.

Safety Considerations for Each Decontamination Method

Chemical decontamination involves the use of hazardous substances such as acids, alkalis, and solvents, requiring strict adherence to safety protocols including proper ventilation, protective gear, and careful handling to prevent chemical burns or inhalation risks. Mechanical decontamination relies on physical methods like scrubbing, blasting, or high-pressure water jets, which carry risks of injury from equipment or airborne debris, necessitating protective barriers and operator training to avoid accidents. Both methods demand rigorous risk assessments and compliance with regulatory safety standards to minimize exposure and ensure safe operational environments.

Choosing the Right Decontamination Method for Your Car

Chemical decontamination effectively removes embedded contaminants like tar, sap, and industrial fallout by breaking down particles at a molecular level, ideal for deep cleaning without abrasive effects. Mechanical decontamination, using clay bars or brushes, physically lifts surface contaminants and is suitable for regular maintenance to restore smoothness and paint clarity. Selecting the right method depends on your car's contamination severity and paint sensitivity, balancing thoroughness with protection to maintain your vehicle's finish.

Chemical Decontamination vs Mechanical Decontamination Infographic

cardiffo.com

cardiffo.com